Products

Product Range

- Fermentation Tank (Yeast/Seed Tank, Tank Crystallizer)

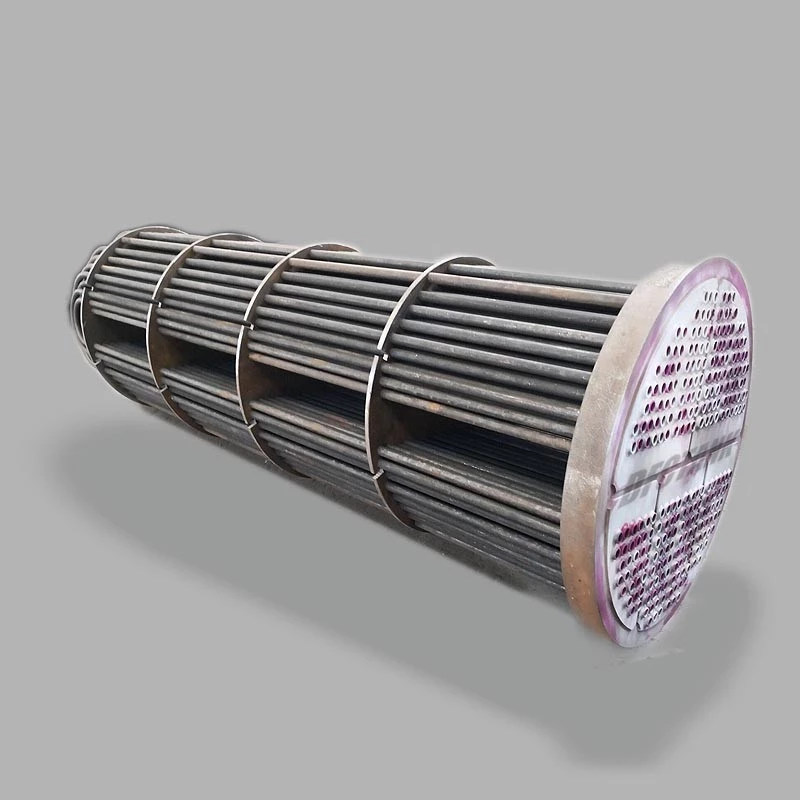

- Heat Exchanger (Air Cooled Heat Exchanger, Finned Tube Bundle)

- Storage Tank (Oxygen/Nitrogen/Argon/Hydrogen Air Storage Tank, Conveying/Blow Tank, Cement Storage Tank, Surge Tank)

- Filter Vessel (Dust Filter, Water Filter, Oil/Gas Filter)

- Large Storage Tank (Sphere/Fixed Roof)

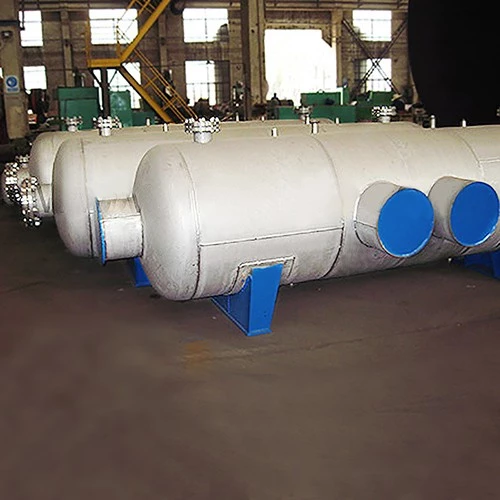

- Separator Vessel (Gas/Steam/Test/Production/Filter Separator)

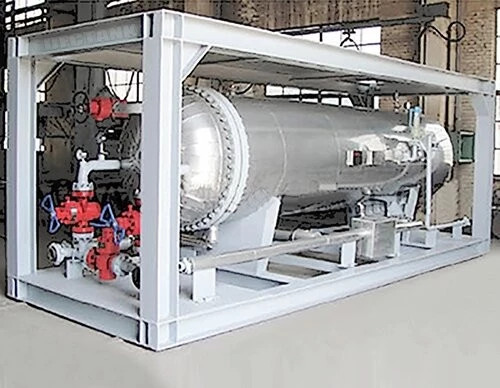

- Skid Mounted Equipment

All our products can be customized. For detailed solutions, please contact us!

FAB has extensive experience in complying with PED (97/23/EC), TR CU 032/2013 and CRN requirements.

FAB has extensive experience in complying with PED (97/23/EC), TR CU 032/2013 and CRN requirements.

We are also familiar with domestic and international norms and standards: ASME Code Section VIII Division 1, AS 1210, TR CU 032/2013, EN 13445, TEMA, API 650, API 620, API 661 and PD 5500.

Plate MaterialCarbon Steel: ASME SA516 Grade 60/ASTM A516 Grade 60, ASME SA516 Grade 70/ASTM A516 Grade 70, ASME SA283/ASTM A283, ASME SA285/ASTM A285

Stainless Steel: ASME SA240 Grade 304/ASTM A240 Grade 304, ASME SA240 TP316L/ASTM A240 TP316L, Stainless Steel 304, Stainless Steel 316L

Titanium

Alloy Steel: UNS N08825, ASME SA387/ASTM A387, ASME SB265 Titanium Grade 1/ASTM B265 Titanium Grade 1, Dual-phase Steel

ASME SA516 Grade 70/ASTM A516 Grade 70 + Clad ASTM A312 TP304

ASME SA516 Grade 70/ASTM A516 Grade 70 + Clad ASTM A312 TP316L

ASME SA516 Grade 70/ASTM A516 Grade 70 + Clad ASME SB265 Grade 1/ASTM B265 Grade 1

ASME SA516 Grade 70/ASTM A516 Grade 70 + Clad UNS N08825

Forging Material: ASME SA105/ASTM A105, ASME SA182/ASTM A182, ASME SA266 Grade 2/ASTM A266 Grade 2, ASME SA350/ASTM A350

Tube Material: ASME SA179 (M)/ASTM A179 (M), ASME SA106B/ASTM A106B, ASME SA213 TP304/ASTM A213 TP304, ASME SA213 TP316L/ASTM A213 TP316L, ASME SB111/ASTM B111, ASME SB338 Grade 2/ASTM B338 Grade 2

Bolt/Nut Material: ASME SA193/ASTM A193, ASME SA194/ASTM A194

Heat Exchanger

China Heat Exchanger Manufacturer FAB supplies industrial shell and tube heat exchangers, air cooled heat exchangers (air cooler), etc.

Material:

- ASME SA179M/ASTM A179M

- Aluminium

- ASME SB111/ASTM B111

- ASME SB111 C44300/ASTM B111 C44300

- Stainless Steel 304

- Stainless Steel 316

FAB's heat exchangers are customized to match your specific requirements. Leveraging standardized calculation programs, we swiftly determine the design parameters of your heat exchanger, ensuring it meets your individual needs with precision and efficiency.

For detailed solutions, please contact us!

Model No.: FAB-240125-HE-09

As a premier Floating Head Heat Exchanger Supplier, we offer top-quality exchangers engineered for high-temperature applications. Our exchangers boast a robust design with a carbon steel ASTM A516 shell and ASTM A179 tubes, ensuring exceptional durability and heat transfer efficiency. Manufactured in strict adherence to ASME VIII Division 1 standards, our products guarantee reliability under pressure, with a maximum operating capacity of 6.4 MPa.

Model No.: FAB-240131-HE-02

As a leading heat exchanger spare parts supplier based in China, we offer a comprehensive range of both OEM and generic spare parts to meet your industrial heat exchanger needs. Our product lineup includes high-quality finned tubes, axial fans, pipe racks, and other essential components essential for efficient heat exchange processes. Whether you require replacement parts for maintenance or upgrades, we provide reliable solutions tailored to your specific requirements.

Model No.: FAB-240122-HE-02

Optimize your hydraulic system's performance with our Hydraulic Water Oil Cooler from China. This Shell and Tube Heat Exchanger, constructed with durable Carbon Steel, offers a versatile solution for heat transfer. With a Heat Transfer Area ranging from 0.5 m² to 500 m², it suits various applications seamlessly. Whether you're cooling oil, water, or air, this cooler ensures efficient heat exchange, contributing to the overall efficiency of your system. Upgrade your hydraulic setup with our reliable Hydraulic Water Oil Cooler for consistent and effective cooling.

Model No.: FAB-240124-HE-06

Optimize your oil heat exchange systems with our Tubular Heat Exchanger. Crafted in compliance with ASME Section VIII Division 1 standards, this exchanger features a robust housing and tube made from high-quality carbon steel. With a tube length extending to 2.4 x 11.5 meters, this exchanger is designed for maximum efficiency in oil heat exchange applications. Upgrade your systems with our reliable and precision-engineered Tubular Heat Exchanger for superior performance.

Filter Vessel

FAB, a leading industrial manufacturer and supplier of filter vessels and tanks based in China, delivers tailored filtration solutions for water and fuel treatment as well as gas purification.

With decades of expertise, FAB has built a strong reputation for crafting customized filtration vessels, including water treatment filters, dust filters, and fuel filters, to meet the unique needs of our clients.

With decades of expertise, FAB has built a strong reputation for crafting customized filtration vessels, including water treatment filters, dust filters, and fuel filters, to meet the unique needs of our clients.

Type

- Sand filter

- Aviation fuel filter

- Fuel oil filter

- Ion exchange resin water filter

- Coalescing filter

- Scrubber

Material

- Carbon Steel: ASME SA516 Grade 70/ASTM A516 Grade 70, ASME SA516M Grade 70 (485)/ASTM A516M Grade 70 (485)

- Stainless Steel: Stainless Steel 304

- Alloy: 16MnR, Q345R

Manufacturer Code

- ASME Section VIII Division 1

- GB 150

- TR CU 032/2013

- ASME VIII Division 1 + Subsection NB

Model No.: FAB-240126-OF-07

Our carbon steel filter vessels, crafted to exacting standards, are forged from ASTM A516 Grade 70 steel, adhering to ASME VIII Division 1 and EN 13445 regulations, as well as GB 150 standards. Operating at a pressure of 0.65 MPa, these vessels offer a capacity of approximately 160 gallons, making them ideal for the filtration of jet and aviation fuel. Built with precision and durability, they ensure efficient and reliable performance in critical fuel handling processes.

Model No.: FAB-240122-OF-01

Manufactured to the highest standards, our Lube Oil Filter Vessels are crafted from durable Low Alloy Steel Q345R, ensuring strength and resilience. In compliance with GB 150 regulations, these vessels boast an impressive internal diameter of 800 MM and a height of 1500 MM (31 x 59 Inch). Engineered for optimal performance in oil filtration systems, they operate at a pressure of 1.7 Mpa (246 PSI), making them a reliable choice for various industrial applications.

Model No.: FAB-240123-OF-01

Our Aviation Fuel Filter Vessel, expertly crafted by a leading fabricator, features top-notch materials such as ASTM A516 70 and Q345R to ensure durability. Built in accordance with ASME VIII-1 and EN 13445 standards, this vessel measures 19 x 59 inches and operates at a pressure of 94 PSI. With a volume of 0.6 m³, it's specifically designed for bulk fuel filtration, making it a reliable choice for aviation fuel applications. Trust in the quality and precision of our Aviation Fuel Filter Vessel for your filtration needs.

Model No.: FAB-240123-OF-02

Our Fuel Filter Vessel, proudly manufactured in China, boasts top-grade ASTM A516M Grade 485 material, ensuring high-quality performance. Compliant with ASME VIII-1 standards, this vessel operates at a pressure of 232 PSI, making it suitable for demanding applications in thermal power and the marine industry. With dimensions of 31 x 47 inches and a design temperature of 80℃, it's tailored to deliver reliable and efficient filtration for various industrial needs.

Storage Tank

China industrial storage tank manufacturer FAB offers

- Air storage tank (oxygen/nitrogen/argon/hydrogen)

- Stainless steel tank (especially for the pharmaceutical industry)

- Conveying/Blow tank

- Cement storage tank (storage silo)

- Surge tank (surge vessel)

Our storage tanks are designed according to specific requirements.

Please contact us for detailed solutions!

Model No.: FAB-240124-LST-01

Discover our Field Erected Tank, designed for Above Ground Bulk Water Storage, specifically tailored for Fire Protection needs. Manufactured in accordance with API 650 standards and crafted from durable ASTM A36 materials, this tank stands at an impressive 400,000 gallons. With dimensions of ID 13,000 MM x Height 8,000 MM, it ensures a reliable and substantial water storage solution for fire protection applications. Rely on our expertise in providing top-quality Field Erected Tanks to meet your specific requirements.

Model No.: FAB-240124-LST-02

Elevate your storage solutions with our state-of-the-art Fixed Roof Storage Tank, meticulously manufactured to meet the highest standards. Crafted in a welded configuration according to API 650 and GB 50341 specifications, this tank ensures durability and reliability. Made from high-quality SS400, it boasts a full capacity of 400 m³, accommodating various storage needs. With a pressure range from -490 PaG to 20,000 PaG, this tank provides versatility for diverse industrial applications.

Model No.: FAB-240122-LOT-01

We specialize in manufacturing Cryogenic Liquid Oxygen Bulk Tanks, available in both vertical and horizontal types. Our tanks adhere to ASME and PED standards, offering capacities ranging from 5 to 200 cubic meters. Operating at pressures of 8 and 16 bars, these tanks feature a Q245-R outer shell for strength and durability, coupled with a corrosion-resistant Stainless Steel S30408 inner shell. Our state-of-the-art production ensures top-quality tanks for reliable and efficient cryogenic liquid oxygen storage.

Model No.: FAB-240122-LOT-02

We specialize in manufacturing Medical Oxygen Storage Cylinders designed for vertical installation. These cylinders adhere to ASME and PED standards, offering a wide range of capacities from 5 to 200 cubic meters. Operating at pressures of 8 and 16 bars, our cylinders feature a robust carbon steel outer shell for durability, coupled with a corrosion-resistant stainless steel inner shell. Our commitment to quality ensures reliable and safe storage of medical oxygen for various applications.

Fermentation Tank

FAB's fermentation vessels include industrial fermentation tanks, seed tanks, yeast tanks, circulation tanks, crystallization tanks.

Our fermentation tanks can be made of stainless steel 304, alloy steel Q345R, ASME SA516 Grade 70/ASTM A516 Grade 70, etc.

As a leading fermentation tank manufacturer, our expertise is demonstrated through a rich history of serving diverse projects within the pharmaceutical industry. From the Penicillin Project to the 3000-ton Penicillin Project, the 6APA Cephalosporin Project, and beyond, our fermentation tanks have played pivotal roles in numerous endeavors including the Oxytetracycline Project, B12 Project, Streptomycin Project, Vitamin Project, and the Abamectin Project.

We understand that each project comes with unique requirements, which is why the capacity of our fermentation tanks is tailored to meet your specific needs. Utilizing standardized calculation programs, we ensure swift determination of design parameters, allowing us to promptly deliver fermentation tanks that align precisely with your individual requirements.

Please contact us for more information!

As a leading fermentation tank manufacturer, our expertise is demonstrated through a rich history of serving diverse projects within the pharmaceutical industry. From the Penicillin Project to the 3000-ton Penicillin Project, the 6APA Cephalosporin Project, and beyond, our fermentation tanks have played pivotal roles in numerous endeavors including the Oxytetracycline Project, B12 Project, Streptomycin Project, Vitamin Project, and the Abamectin Project.

We understand that each project comes with unique requirements, which is why the capacity of our fermentation tanks is tailored to meet your specific needs. Utilizing standardized calculation programs, we ensure swift determination of design parameters, allowing us to promptly deliver fermentation tanks that align precisely with your individual requirements.

Please contact us for more information!

Model No.: FAB-240124-FT-04

Explore the excellence of our Stainless Steel Yeast Tank, dedicated to yeast fermentation in your processes. Crafted with precision from high-quality SS 316L, this tank adheres to the rigorous standards of ASME Section VIII Division 1, EN 13445, and GB 150. With a generous capacity of 9642 Gallons and dimensions of 2700 x 10322 MM, it provides the ideal environment for yeast cultivation. Operating effortlessly at pressures up to 0.3 MPa, this tank is a reliable choice for ensuring the success of your yeast fermentation processes.

Model No.: FAB-240124-FT-01

Introducing our Antibiotic Fermentation Tank, a pinnacle of engineering for penicillin fermentation. Constructed from high-quality Alloy Steel ASTM A516 Grade 70, this tank adheres to stringent ASME VIII Division 1 standards, ensuring reliability and safety. With an impressive capacity of 26,417 gallons, it operates at a pressure of 0.3 MPa, making it the ideal solution for large-scale antibiotic production. Rely on our commitment to excellence for your fermentation needs.

Model No.: FAB-240124-FT-02

Welcome to our Agitated Tank Crystallizer, meticulously crafted for Streptomycin manufacturing. Constructed with precision using Stainless Steel 304, this crystallizer adheres to the rigorous standards of ASME Section VIII Division 1 and EN 13445. With dimensions of 1200 MM x 1500 MM and a robust design, it can withstand pressures of 1.7 MPa, ensuring optimal performance for your crystallization processes. Trust in our commitment to quality for your pharmaceutical manufacturing needs.

Model No.: FAB-240124-FT-03

Introducing our Yeast Propagation Tank, a pinnacle of quality and precision for the B12 Project. This tank is expertly crafted from Stainless Steel SS 304, meeting the stringent standards of ASME Section VIII Division 1 and EN 13445. With a capacious 3487 Gallon capacity and an interior diameter ranging from 1500 to 1800 MM, it provides the ideal environment for yeast propagation. Engineered to handle pressures up to 0.3 MPa, this tank is your trusted partner for ensuring optimal conditions in yeast cultivation.

Separator Vessels

China separator vessels manufacturer FAB provides Various separator vessels in different materials and sizes.

Product Rangs:

- Ammonia Separator Vessels

- Steam-Water Separator Vessel

- Production Separator Vessel

- Baffle Steam Separator Vessel

- Well Test Separator

- Three Phase or Two Phase

- Vertical or Horizontal

Design Code: ASME Section VIII Division 1

Model No.: FAB-240124-SV-05

The Stainless Steel SS 304 Ammonia Separator Vessel is designed for ammonia refrigeration equipment. It adheres to ASME VIII Division 1 and EN 13445 standards, features a vertical orientation, and operates at a pressure rating of 2.5 MPa. With an inner diameter of 1400 x 16 MM, it ensures efficient separation of ammonia in industrial refrigeration systems.

Model No.: FAB-240315-SV-01

Manufactured at the Steam-Water Separator Vessel Mill, this vessel is crafted from carbon steel, meeting the standards of ASME SA516 Grade 70 and ASTM A516 Grade 70. With an inner diameter of 2286 millimeters, it boasts a customized design and dimensions tailored to specific requirements. The equipment bears the ASME U stamp, ensuring compliance with quality and safety standards.

Model No.: FAB-240124-SV-01

Enhance your oilfield well testing operations with our Vertical Well Test Separator. Manufactured in accordance with ASME Section VIII Division 1 standards and crafted from durable ASTM A516 Grade 70 and ASME SA516 Grade 70 materials, this separator is designed for optimal performance in well testing applications. Trust our expertise in delivering high-quality equipment to meet the demanding requirements of the oil and gas industry.

Model No.: FAB-240124-SV-02

Optimize your oil, gas, and water separation processes with our Horizontal Three-Phase Separator Vessel. Crafted from robust Carbon Steel ASTM A516 Grade 70, this vessel meets the highest standards of ASME Section VIII Division 1. Engineered for efficiency, reliability, and durability, our separator ensures effective separation of oil, gas, and water components. With a maximum pressure rating of 1.05 MPa, it is ideal for diverse applications in the oil and gas industry.

Stainless Steel Tank

FAB, a professional pressure vessel manufacturer in China, supplies durable & cost-effective stainless steel pressure vessels, stainless steel tanks for industrial applications.

Category

- Filter Tank

- Vacuum Tank

- Measuring Tank

- Liquid Storage Tank

Material

- Stainless Steel 304

- Stainless Steel 316L

Standard

- GB 150

- ASME Section VIII Division 1

- Pharmaceutical Industry (B12/Penicillin/Streptomycin/6APA Cephalosporin/Oxytetracycline Project)

- Hygienic Industry

- Food Industry

Model No.: FAB-240131-SST-01

We specialize in manufacturing vertical stainless steel liquid storage tanks. Crafted from high-grade SS 316L and built to GB 150 and ASME VIII Division 1 standards, our tanks ensure quality and reliability. With a maximum capacity of 13,208 gallons and a diameter of 102 inches, they meet diverse storage needs with efficiency and durability.

Model No.: FAB-240125-SST-01

At our Stainless Steel Storage Silo Plant, we specialize in crafting high-quality storage solutions tailored for the food and pharmaceutical industries. Utilizing SS 304, also known as SUS 304, our silos meet rigorous standards like ASME VIII Division 1 and EN 13445, ensuring reliability and safety. With an inner diameter of 1500 MM and designed for the B12 Project, our silos provide efficient bulk storage capabilities, safeguarding your valuable products with precision engineering and quality materials.

Model No.: FAB-240125-SST-02

As a leading Stainless Steel SS 304 Scrubber Manufacturer, we adhere to the stringent standards of ASME Section VIII Division 1 to ensure top-notch quality. With an inner diameter of 1200 MM, our scrubbers are designed to withstand pressures of up to 0.4 MPa, making them ideal for various industrial applications. Operating at temperatures below or equal to 160°C, our scrubbers effectively remove contaminants, providing a clean and safe environment. Trust our expertise for reliable and efficient stainless steel scrubbers tailored to your needs.

Model No.: FAB-240125-SST-03

As a premier Stainless Steel SS 304 Storage Tank Supplier in China, we adhere to industry-leading standards such as ASME Section VIII Division 1, GB 150, and EN 13445 to ensure exceptional quality and reliability. With an inner diameter of 1500 MM, our tanks are meticulously designed for the demanding requirements of projects like Streptomycin production. Count on us for robust storage solutions that meet the highest standards of safety and performance, tailored to your specific needs.

High Pressure Vessel

FAB is a Chinese pressure vessel manufacturer with technical sophistication. We pride ourselves on our U stamp/ASME high-quality pressure vessels adopted for pharmaceutical industry, food industry, refinery industry, etc.

- Fermentation tank: seed tank, yeast tank, circulation tank, crystallization tank, etc.

- Heat exchanger: industrial heat exchanger, air cooler, tube bundle, finned tube, etc.

- Storage tank: air storage tank, stainless steel tank, conveying tank, cement storage silo, surge tank, etc.

- Filter: dust filter, filter for water treatment, aviation fuel filter, fuel oil filter, coalescing filter, etc.

FAB's high pressure vessels can be customized according to your requirements.

Please contact us for detailed solutions!Model No.: FAB-240122-PV-01

We supply high-quality Carbon Steel Flash Vessels with ASME SA516 70 and ASME SA516M 70 Steel Plate construction. Our vessels also incorporate ASME SA20, ASME SA20M, and ASME SA105M Flanges, ensuring durability and reliability. The manufacturing process includes a precise Shell Rolling Procedure, delivering robust and dimensionally accurate products.

Model No.: FAB-240122-PV-02

Our China-based factory specializes in producing secondary ammonia chillers, adhering to stringent standards such as ASTM A516 70. Custom dimensions are available to meet diverse project requirements. The chiller materials include ASTM A105 and AISI 4017, ensuring robust performance under challenging conditions with a maximum pressure rating of 27.5 MPa. Featuring an impressive heat exchange area of F=500 m², these chillers undergo Method B ammonia leakage testing for enhanced safety and reliability.

Model No.: FAB-240122-PV-03

Our state-of-the-art facility in China proudly manufactures primary ammonia chillers, crafted to the highest standards. These chillers are constructed using ASTM A516 Grade 70 and AISI 4017 materials, ensuring exceptional durability and reliability. With dimensions of φ1200/1800*20*4500, these chillers boast a maximum pressure rating of 27.5 MPa, making them suitable for demanding applications. The heat exchange area stands at F=200 m², and the chiller tubes are made from Q345E for efficient heat transfer.

Model No.: FAB-240122-PV-04

Our cutting-edge manufacturing facility produces high-quality waste heat recoverers designed for optimal performance. These recoverers are constructed with ASTM A387 Grade 12 material, ensuring durability and efficiency. The dimensions, including φ1400/1000*4800, make them suitable for various applications. The recoverer tubes, with dimensions Φ32*3, provide an impressive heat exchange area of F=370 m². Despite their robust capabilities, these units are relatively lightweight at 36.7 tons.

Surge Tank

A surge tank is an attachment to a pressurized system designed to accommodate pressure changes.

The surge tank is designed to neutralize pressure rises and pressure falls to prevent system failures, blowouts, etc. Furthermore, the surge tank offers effective methods for measuring liquid flow rates, shrinkage and meter factors.

The surge tank is designed to neutralize pressure rises and pressure falls to prevent system failures, blowouts, etc. Furthermore, the surge tank offers effective methods for measuring liquid flow rates, shrinkage and meter factors.

Code

- PED

- PD 5500

- ASME Section VIII Division 1

Medium

- Potable Water

- Crude Oil

Application

- Well Testing

Model No.: FAB-240124-SGT-02

Introducing our Crude Oil Surge Tank designed for optimal functionality in a horizontal configuration. This tank, constructed according to ASME VIII Division 1 standards, features a 50-barrel capacity, equivalent to 2,100 US gallons. Specifically crafted for measuring liquid flow rates, our surge tank is equipped with features such as shrinkage and a meter factor to ensure accurate and reliable performance. Trust our commitment to precision and quality in providing solutions tailored to your requirements in the oil and gas industry.

Model No.: FAB-240131-ST-02

As a premier bladder surge vessel factory based in China, we specialize in manufacturing high-quality vessels tailored to meet diverse industrial needs. Our surge vessels are constructed from top-grade materials, including ASME SA516M 485 and ASTM A36, ensuring durability and reliability. With a design pressure of 5.0 MPa and compliance with ASME VIII Division 1, Ed.2017 standards, our φ1500 x 2350 x 32 MM vessels offer a maximum volume of 300 m³, providing efficient storage and surge capacity for various applications.

Model No.: FAB-240131-ST-01

As a leading supplier of potable water surge tanks, we offer robust solutions crafted from carbon steel ASTM A516M Grade 485. Our tanks adhere to PED, PD 5500, and EN 13445 standards, ensuring safety and quality. With a capacity of approximately 40,000 gallons and an inner diameter of 2600 mm, our surge tanks are designed to meet the demands of water distribution systems with reliability and efficiency.

Model No.: FAB-240124-SGT-01

Explore our Crude Oil Surge Tank, meticulously designed in a vertical configuration to meet the demanding requirements of Oil and Gas Well Testing. Crafted in accordance with ASME VIII Division 1 standards, this tank boasts a capacity of 100 barrels or 4,200 US gallons. With dimensions measuring 1,900 MM in diameter and 6,500 MM in height, our surge tank provides a reliable and efficient solution for handling crude oil in the challenging conditions of well testing in the oil and gas industry.

Air Cooled Heat Exchanger

We are a professional manufacturer specializing in producing Air Cooled Heat Exchanger, Air Cooler Tube Bundles, Industrial Air Cooler Frame, as per codes like ASME VIII Division 1, API 661, etc.

Model No.: FAB-240131-ACHE-01

As a reputable air cooling unit frame manufacturer in China, we adhere to the design codes of ASME VIII Division 1 and API 661 to ensure compliance and quality. Our frames are customized to meet your specific requirements, offering flexibility in body materials and featuring a horizontal design for optimal functionality. Trust us to deliver durable, reliable, and tailored solutions for your air cooling needs, backed by our commitment to quality and customer satisfaction.

Model No.: FAB-240131-ACHE-05

Choose from our Industrial Air Cooler Frame Manufacturing facility in China. We specialize in crafting high-quality frames for air-cooled heat exchangers, meticulously designed to meet API 661 and ASME VIII Division 1 standards. Our frames are tailored to fit the precise specifications of air-cooled heat exchangers, ensuring seamless integration and optimal performance. With a focus on customization, we offer a range of materials to suit your specific requirements, guaranteeing durability and reliability in demanding industrial environments.

Model No.: FAB-240122-ACHE-01

Elevate your cooling capabilities with our Air Cooler Tube Bundle from China. Crafted with precision using ASTM A179M-grade aluminum, this bundle ensures efficient heat exchange. With a length of 1000 mm, an outer diameter of 25 mm, and a thickness of 2.5 mm, it strikes the perfect balance between compact design and optimal performance. Operating at a design pressure of 1.0 MPa and designed for temperatures up to 100 ℃, it guarantees reliable and effective cooling for various applications.

Model No.: FAB-240130-ACHE-01

Our cutting-edge air cooler tube bundle manufacturing facility specializes in producing top-quality bundles compliant with ASME VIII Division 1 standards. These bundles feature tubes made from ASTM A179M aluminum alloy, ensuring optimal heat transfer efficiency. With a thickness of 2.77 mm and a design pressure of 0.196 MPa, our bundles are engineered to withstand demanding operating conditions. The finned pipes, measuring 9800 mm in length, enhance heat dissipation, making them ideal for a wide range of cooling applications.

Conveying Tank

FAB provides durable conveying/blow tanks required for conveying systems in power plants and steel plants for decades.

Material: Q345R, ASME SA516 Grade 70/ASTM A516 Grade 70, etc.

Code: GB 150, ASME Section VIII Division 1, EN 13445, etc.

Volume:

1.5 m3, 2.5 m3, 3 m3, 4 m3, etc.

396 Gallon, 660 Gallon, 792 Gallon, 1056 Gallon, etc.

Application: Power plants, steel plants, cement industry, gypsum industry, refinery industry, etc.

Model No.: FAB-240126-CT-01

As a leading blowdown tank fabricator in China, we specialize in crafting high-quality tanks tailored for refinery applications. Our tanks, constructed from ASTM A516 Grade 70 steel and compliant with ASME VIII Division 1 and EN 13445 standards, boast an inner diameter of 2000 MM. With a capacity of 1050 US gallons and a design pressure of 1.0 MPa, our tanks are engineered to efficiently manage blowdown processes in refinery operations, ensuring safety and reliability.

Model No.: FAB-240130-CT-03

Discover our premium carbon steel blow tank, engineered for the rigorous demands of the cement industry. Constructed from durable Q345R material and reinforced with ASTM A516 Grade 70 compliance, this tank ensures robust performance and longevity. Designed to meet ASME VIII Division 1, GB 150, and EN 13445 standards, it guarantees reliability under challenging conditions. With a capacity of 792 gallons and a pressure rating of 1.0 MPa, it offers ample storage and efficient operation.

Model No.: FAB-240130-CT-02

Explore our low alloy steel blow tank, meticulously engineered for power plant conveying systems. Crafted from robust Q345R material and fortified with ASTM A516 Grade 70 compliance, this tank ensures superior durability and performance. Meeting stringent EN 13445, GB 150, and ASME VIII Division 1 standards, it guarantees reliability under demanding conditions. With a diameter of 1200mm and a capacity of 660 gallons, it's perfectly sized for efficient material handling. Trust in its quality for seamless integration into your power plant operations.

Model No.: FAB-240130-CT-01

Introducing our ASTM A516 Grade 70 blow tank, meticulously crafted for steel mill conveying systems. Engineered with durable Q345R material and compliant with GB 150, ASME VIII Division 1, and EN 13445 standards, this tank ensures top-tier performance and safety. Its 1200mm diameter accommodates 264 gallons (1000 liters) of material, operating flawlessly at 1.0 MPa pressure. Trust in its efficiency and reliability for seamless integration into your industrial operations.

Skid Mounted Equipment

China skid-mounted equipment manufacturer FAB offers skid-mounted process equipment, skid mounted system, oil field equipment, minimize installation time. We provide customized skid-mounted equipment including Skid-mounted Separators, Heat Exchangers, Filter Separators, Surge Tanks, and Compressors.

If products shown on our website cannot meet your requirements, please contact us.

If products shown on our website cannot meet your requirements, please contact us.

Customized Steam Heat Exchanger Skid

Model No.: FAB-240123-OF-03

Introducing our Filter Separator Vessel, expertly crafted in China with precision and reliability in mind. Constructed from high-quality Stainless Steel SS 304, this vessel meets the stringent standards of ASME VIII-1, EN 13445, and GB 150. Designed for versatility, it features a compact 219mm (8.6 inches) horizontal structure, making it suitable for a range of applications. The added convenience of being skid-mounted enhances its mobility and ease of installation.

Model No.: FAB-240124-SGT-01

Explore our Crude Oil Surge Tank, meticulously designed in a vertical configuration to meet the demanding requirements of Oil and Gas Well Testing. Crafted in accordance with ASME VIII Division 1 standards, this tank boasts a capacity of 100 barrels or 4,200 US gallons. With dimensions measuring 1,900 MM in diameter and 6,500 MM in height, our surge tank provides a reliable and efficient solution for handling crude oil in the challenging conditions of well testing in the oil and gas industry.

Model No.: FAB-240126-SV-02

Our horizontal separator vessel plant specializes in crafting three-phase design vessels built to ASME VIII Division 1 standards. Constructed from ASME SA516 Grade 70 material, these vessels ensure robustness and reliability. With an internal diameter measuring 1066 x 46 millimeters, they accommodate various industrial needs. Designed to withstand pressures of up to 10 MPa, these vessels excel in separating oil, gas, and water streams efficiently.

Model No.: FAB-240126-OF-01

Our industrial filter separator vessels boast a skid-mounted design for ease of installation. Constructed from robust stainless steel SS 304 and compliant with GB 150, ASME VIII Division 1, and EN 13445 standards, they ensure reliable operation. With a diameter of 219 mm, they're tailored to meet diverse industrial filtration needs.