Accumulators play a crucial role in fluid power systems, serving various functions. They are employed to store energy and mitigate pulsations. In hydraulic systems, they contribute to reducing the fluid pump's specifications by supplementing the pump's fluid during low-demand phases. This involves storing energy in the pump when demand is minimal. Accumulators act as buffers and absorbers, smoothing out fluctuations and pulses, cushioning impacts, and reducing vibrations resulting from abrupt starts or stops of power cylinders in hydraulic circuits. Additionally, accumulators help stabilize pressure changes caused by temperature fluctuations in the hydraulic system. They also facilitate the distribution of pressurized fluids, such as grease and lubricating oil.

Currently, the most widely used accumulator is the pneumatic-hydraulic type. The gas's action, similar to that of a buffer spring, collaborates with the fluid and is separated by a gas piston, a thin diaphragm, or an airbag.

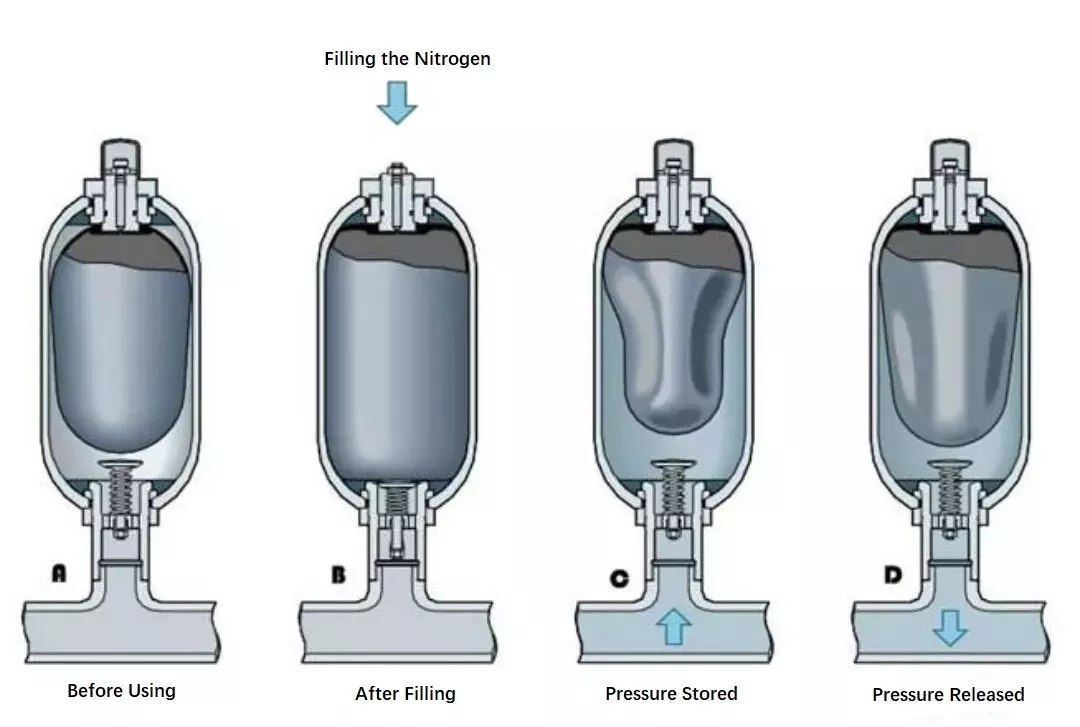

The Working Principle of the Accumulator

The hydraulic accumulator serves a critical role in hydraulic systems, particularly in maintaining pressure and supplementing fluid. When subjected to liquid pressure, the minimal volume change at the same temperature can lead to rapid pressure loss if there is no power source, such as high-pressure liquid supplementation. In contrast, gas, being compressible, maintains relatively high pressure even with significant volume changes. The accumulator, replenishing hydraulic oil in the hydraulic system, utilizes high-pressure gas to sustain oil pressure, preventing rapid pressure loss due to volume changes during oil replenishment.

Nitrogen is commonly used due to its stability, lack of oxidation or reduction properties, and its positive impact on maintaining hydraulic oil performance without causing denaturation. Pre-charging nitrogen in the accumulator's airbag, separated from hydraulic oil, ensures pressure equalization during oil filling. As hydraulic oil enters, the compressed nitrogen airbag increases pressure until the set pressure is reached.

The main function of the accumulator includes:

Auxiliary Power Supply:

The accumulator acts as an auxiliary power source for hydraulic systems with intermittent actuation, allowing the use of a low-power pump to reduce the main drive's power, resulting in a smaller, lighter, and more cost-effective hydraulic system.

Emergency Power Source:

In situations where the pump fails or power is cut off, requiring actuators to complete essential actions, the accumulator serves as an emergency power source to ensure necessary operations, such as retracting the piston rod for safety reasons.

Leakage Compensation and Pressure Maintenance:

For systems where actuators remain inactive for extended periods but require constant pressure, the accumulator compensates for leakage, maintaining a constant pressure.

Hydraulic Impact Absorption:

Absorbing sudden changes in fluid flow caused by valve reversals, pump stops, or emergency braking, the accumulator mitigates impact pressure, preventing damage to instruments, components, and pipelines while reducing system vibration.

Pulsation Absorption and Noise Reduction:

Connecting an accumulator in parallel at the pump's outlet absorbs flow and pressure pulsations, reducing noise and ensuring smoother actuator movement by countering the effects of pulsating pump flow.

In summary, the accumulator's versatile functions contribute to enhancing the efficiency, safety, and stability of hydraulic systems.