What Are Different Types Shell-and-Tube Heat Exchangers

On this page

Shell and tube heat exchangers are widely used in industrial applications due to their versatile design, which allows them to adapt to various operating conditions, including different types of media, pressure, temperature, and environmental changes. The basic structure of a shell and tube heat exchanger involves connecting tubes to a tube sheet, which is then secured within a shell. These heat exchangers come in several types, including fixed tube sheet, floating head, U-tube, sliding tube sheet, packed gland, and double pipe designs, each catering to specific operational needs. Below is a detailed overview of the main types of shell and tube heat exchangers, highlighting their characteristics, advantages, disadvantages, and suitable applications.

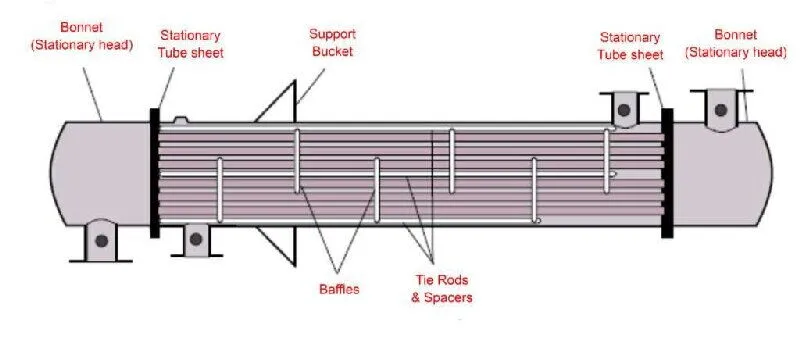

Fixed Tube Sheet Heat Exchanger

After discussing the general structure and applications of shell and tube heat exchangers, we will delve into the design and functionality of different types, starting with one of the most common types: the fixed tube sheet heat exchanger.

1. Characteristics and Advantages

The fixed tube sheet heat exchanger is one of the most common types in the shell and tube category, known for its simple structure and relatively low cost. In this design, both ends of the tube sheet are welded to the shell, and the heat exchange tubes are densely packed, allowing for the maximum number of tubes to be accommodated within the same shell diameter. A significant advantage of this design is its flexibility in setting the number of tube passes, which can be configured in any even number, thereby enhancing the heat exchange efficiency.

2. Disadvantages and Limitations

However, because the tube sheet is fixed to the shell, cleaning the shell side is challenging, making mechanical cleaning impossible. Therefore, fixed tube sheet heat exchangers are not suitable for media that easily form scale. If there is a large temperature difference between the tube bundle and the shell, thermal expansion can cause the tubes to detach from the tube sheet, leading to leaks. To mitigate thermal stress caused by temperature differences, an expansion joint is often welded onto the shell, although this only partially alleviates the problem and cannot eliminate it entirely.

3. Suitable Applications

This type of heat exchanger is suitable for conditions where temperature differences are not significant or where the shell-side pressure is not high, especially in situations where shell-side fouling is not severe or can be maintained through chemical cleaning. Due to its simple structure and low cost, fixed tube sheet heat exchangers are widely used in industrial applications, particularly under ambient temperature and pressure conditions with relatively clean fluids.

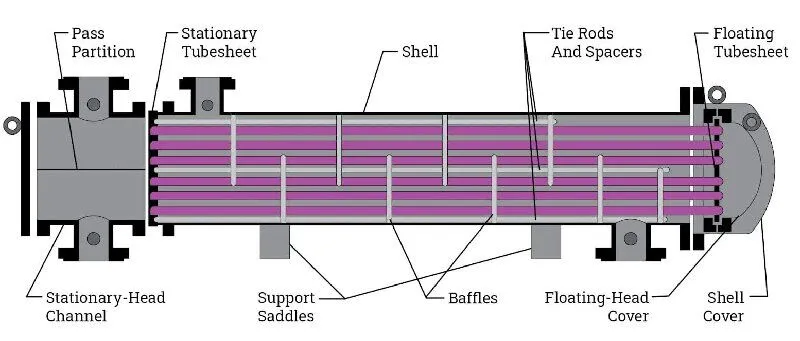

Floating Head Heat Exchanger

Next, we will explore another common type of shell and tube heat exchanger: the floating head heat exchanger.

1. Characteristics and Advantages

The floating head heat exchanger is designed to address the thermal stress issues of fixed tube sheet heat exchangers. In this design, only one end of the tube sheet is fixed to the shell, while the other end, known as the floating head, can move freely within the shell. This design allows the tube bundle and shell to expand freely, effectively preventing thermal stress when there is a large temperature difference between the media. Additionally, the floating head end is designed to be detachable, allowing the tube bundle to be easily inserted or removed, which facilitates maintenance and cleaning.

2. Disadvantages and Limitations

Despite its advantages in handling high-temperature differences and fouling environments, the floating head heat exchanger has a more complex structure and a higher manufacturing cost, typically about 20% more than the fixed tube sheet type. Moreover, the seal at the floating head end cannot be directly monitored for leaks during operation, so special attention must be paid to sealing during installation. Also, due to the larger gap between the shell and tube bundle in floating head heat exchangers, there may be fluid bypassing, affecting heat transfer efficiency, which requires careful design consideration.

3. Suitable Applications

Floating head heat exchangers are suitable for situations with large temperature differences, corrosive or fouling fluids, and where frequent cleaning and maintenance are required. They are widely used in industries such as chemical, petrochemical, and refining, where stable operation under high-temperature and high-pressure conditions is essential.

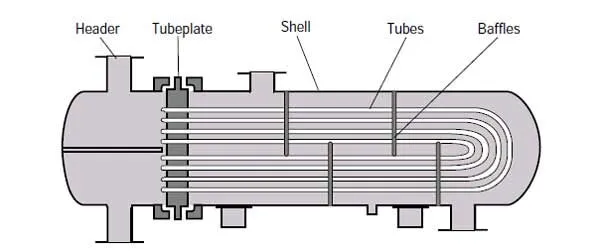

U-Tube Heat Exchanger

After understanding the fixed tube sheet and floating head heat exchangers, we now turn to a uniquely designed type: the U-tube heat exchanger.

1. Characteristics and Advantages

The U-tube heat exchanger has only one tube sheet, with tubes bent into a U shape and both ends fixed to the same tube sheet. This design separates the tube bundle from the shell, allowing the tube bundle to expand and contract freely, thus providing excellent thermal compensation and minimizing thermal stress. U-tube heat exchangers have a simple structure, are relatively low-cost, and offer excellent heat transfer performance. They can withstand high pressures, and the tube bundle can be withdrawn from the shell for external cleaning.

2. Disadvantages and Limitations

The main disadvantage of U-tube heat exchangers is the difficulty in cleaning the inside of the tubes, making them suitable for clean, non-scaling fluids. Additionally, the curved U-shape of the tubes results in a less compact arrangement, and replacing tubes can be complex, especially for inner tubes. Due to design limitations, fluid may short-circuit in the center of the tube bundle, affecting heat transfer efficiency. Therefore, dummy tubes or intermediate baffles are often used to reduce flow dead zones within the exchanger.

3. Suitable Applications

U-tube heat exchangers are ideal for high-temperature and high-pressure operations, especially in environments requiring high pressure. They are commonly used in industries such as refining, chemical processing, and power generation, particularly where equipment performance must be stable under high pressure and temperature conditions.

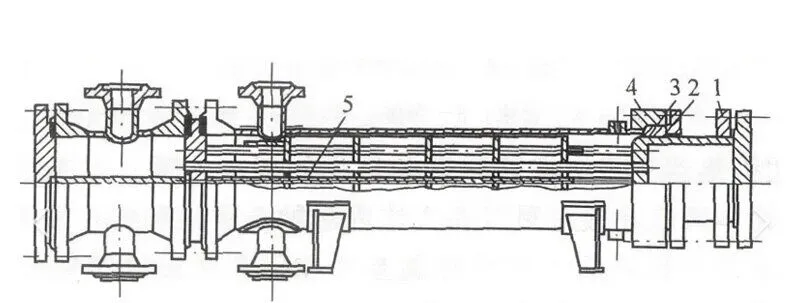

Stuffing Box Heat Exchanger

Lastly, we will discuss a type of shell-and-tube heat exchanger that features a more flexible structure and greater adaptability—the stuffing box heat exchanger.

1. Characteristics and Advantages

The stuffing box heat exchanger combines the benefits of both floating head and fixed tube sheet heat exchangers, while also addressing some of the drawbacks of the fixed tube sheet design. One end of the tube sheet is fixed to the shell, while the other end uses a stuffing box seal, allowing the tube bundle to expand freely and reducing thermal stress caused by temperature differences. The stuffing box heat exchanger has a relatively simple structure, making it easy to manufacture and maintain, with lower costs, and it is suitable for applications that require frequent cleaning.

2. Disadvantages and Limitations

Despite its simplicity and ease of maintenance, the stuffing box heat exchanger is prone to leakage due to the stuffing box seal, making it unsuitable for high shell-side pressure applications, especially in environments handling volatile, flammable, explosive, or toxic media. Additionally, the use of stuffing box heat exchangers is typically limited to smaller equipment with diameters below 700mm. Their application is further constrained in situations with high operating pressures and temperatures.

3. Applications

Stuffing box heat exchangers are primarily used in conditions where the medium is highly corrosive, temperature differences are large, and frequent tube bundle replacement is required. Due to their relatively simple manufacturing and maintenance, they are suitable for small to medium-sized heat exchange tasks in general industrial and chemical sectors.

Shell and tube heat exchangers play a crucial role in industrial production, offering diverse designs to meet various complex operating conditions. Selecting the appropriate type of heat exchanger requires a comprehensive consideration of factors such as media characteristics, operating conditions, economic costs, and maintenance convenience. Understanding the characteristics and applications of different types of heat exchangers can help engineers make optimal decisions during design and selection, ensuring safe, stable, and efficient system operation.