The Vital Role of Surge Tanks in Oil Well Production

On this page

In today's petroleum industry, the stability and efficiency of oil well production systems are paramount. Surge tanks, as a key component, play a vital role in balancing system pressure and ensuring safe equipment operation. Their function is akin to the buffering effect of blood in the human circulatory system, capable of regulating internal pressure fluctuations to ensure the smooth operation of the entire production process. This article delves into the role, structure, and different types of surge tanks in oil well production, providing comprehensive guidance for readers.

Key Function of Surge Tank

The primary function of surge tanks is to alleviate sudden fluctuations in fluid pressure, thus protecting equipment from damage due to overpressure. When fluid pressure in oil well production suddenly increases, surge tanks absorb the excess pressure to maintain system stability. Conversely, when fluid pressure decreases, they release stored gas to maintain system balance. Surge tanks play a crucial role in mitigating pressure fluctuations in various systems, ensuring smoother operation.

Its Structure and Working Principle

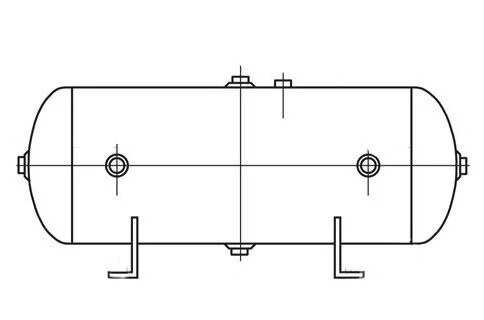

Surge tanks are mainly composed of key components such as pressure vessels, level gauges, inlet and outlet valves, and safety valves. Their working principle relies on the compressibility of liquids, storing liquid inside the tank under external force, compressing the gas. When the external force disappears, the compressed gas expands and discharges water. Connected to the water system, surge tanks act as energy storage devices, regulating system pressure fluctuations.

Types and Characteristics

According to different layouts and functional requirements, buffer tanks are mainly divided into three types: vertical, horizontal, and mobile.

- Vertical Surge Tanks: These tanks feature a simple structure, making them easy to install and maintain, suitable for smaller-scale oil well production. Their vertical arrangement minimizes footprint, facilitating convenient layout in limited space. Connected via pipelines to oil wells, they swiftly alleviate fluid pressure, ensuring the smooth operation of oil well systems.

- Horizontal Surge Tanks: Characterized by a cylindrical structure arranged horizontally, these tanks effectively reduce the load on ground installations, suitable for large-scale oil well production. Their design adapts better to the working environment of high-yield oil wells. Horizontal layout helps reduce equipment vibration, enhance system stability, and facilitates routine maintenance and inspection.

- Mobile Surge Tanks: Compact, lightweight, and easily transportable, mobile surge tanks offer greater flexibility and adaptability. They are suitable for job sites requiring frequent equipment relocation, such as temporary oil well projects or emergency maintenance situations. Mobile surge tanks can respond quickly, providing timely and effective support for oil well production.

In conclusion, surge tanks play a crucial role in oil well production. Different types of surge tanks offer unique advantages and suitability for various scenarios, but their core function remains ensuring stable system pressure and safeguarding equipment operation. As oil well production technology continues to evolve, the design and application of surge tanks will continue to be optimized, providing increasingly reliable support for oil field production.