The Unique Advantages of Floating Head Heat Exchangers

On this page

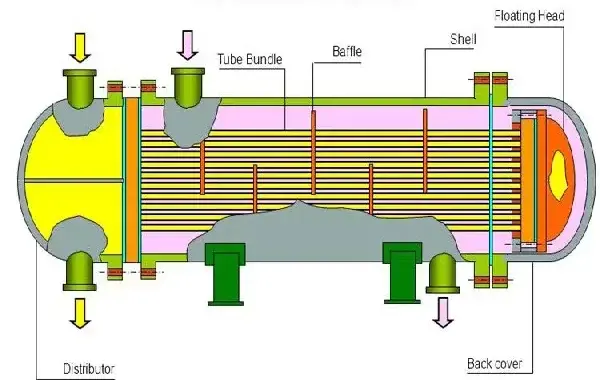

Floating head heat exchangers, as crucial equipment in industrial production, are widely utilized across various process streams due to their excellent heat transfer efficiency and versatile application. Their distinctive floating head structure optimizes the flow path of the medium, significantly enhancing heat transfer effectiveness. Additionally, floating heat heat exchangers are designed for easy operation and maintenance, serving as key tools in improving energy utilization efficiency and production efficiency.

Highly Efficient Heat Transfer

Floating head heat exchangers employ a specially designed floating head structure to optimize the flow path of the medium within the tubes, thereby increasing the contact area between the medium and tube walls. This design not only enhances the heat transfer coefficient and efficiency but also reduces temperature differentials between media, lowering energy consumption, especially beneficial for processes requiring constant temperature.

Flexible Operation and Adjustment Capability

The floating head design of these heat exchangers allows for flexible adjustment and optimization based on different medium characteristics and process requirements. By adjusting the position or changing the structure of the floating head, performance optimization can be achieved to meet varying heat transfer demands under conditions such as high temperature, high pressure, or specific flow rates.

Convenient Maintenance and Cleaning

Due to their relatively simple structure, floating head heat exchangers are easy to dismantle and assemble, facilitating convenient and cost-effective maintenance and cleaning. Operators can quickly replace heat transfer media or perform system cleaning, ensuring long-term stable operation of equipment and minimizing downtime and maintenance costs.

Economically Efficient Operating Costs

Floating head heat exchangers are designed with simplicity, resulting in economically efficient operating costs with minimal energy and resource inputs. Their outstanding heat transfer efficiency not only reduces energy consumption and energy use but also enhances production efficiency and reduces emissions, aligning with modern industrial demands for energy conservation and emission reduction.

High Safety and Reliability

With a simple structure and few mechanical moving parts, floating head heat exchangers have a low failure rate and high safety and reliability. During design and manufacturing, multiple safety measures and protective designs such as explosion-proof devices and pressure protection devices are typically incorporated to ensure the safety of operators and equipment.

Floating head heat exchangers find extensive application in industries such as petrochemicals, power generation, pharmaceuticals, and food processing, particularly in environments where high process stability and high energy utilization efficiency are crucial. With ongoing advancements in industrial technology, floating head heat exchangers will continue to optimize their design and performance to meet increasingly complex and diverse process requirements, providing reliable heat transfer solutions for industrial production.