Large storage tanks play a crucial role in various industries such as petroleum, chemicals, and natural gas extraction, serving as vital components for storing strategic energy resources. Ensuring the safety and stability of these tanks is essential for the uninterrupted functioning of the national economy. Unforeseen events like earthquakes pose a risk of leakage in large storage tanks, resulting in immeasurable losses. To enhance the seismic performance of these tanks, researchers in China have conducted extensive studies on different types, developing theories and implementing improvements to bolster equipment stability.

One notable study focused on the shock absorption performance of spherical storage tanks within the petrochemical industry. Researchers incorporated dampers at the tank's base to enhance stability, attaching them through bolts for effective integration. This innovative approach significantly improved the shock absorption capabilities of the storage tanks. Scholars also delved into the insulation structure of large storage tanks, investigating its impact on the shock absorption performance of LNG (liquefied natural gas) storage tanks. Their findings indicated that an insulation layer could enhance shock absorption and overall reliability to a certain extent.

The seismic and thermal insulation performance of large-scale storage tanks received attention, with scholars conducting numerical simulations to analyze seismic indices and fluid heat transfer in super-large storage tanks. This theoretical groundwork serves as a valuable reference for optimizing the seismic performance of these substantial storage units.

Comparative studies assessed the earthquake-induced shaking of different large storage tank types, employing simulations to identify the most resilient structures. Scholars explored the anti-periodic vibration performance of vertical storage tanks, laying the theoretical foundation for stability design. Analyzing vibration data from seismic events, researchers established a seismic performance grade response library, facilitating the design of interactive systems for tank seismic applications and offering insights for reliable engineering applications.

To further enhance the seismic reliability of large-scale vertical oil storage tanks in China, researchers utilized numerical simulation methods combined with fluid-structure coupling theory. This comprehensive approach provides valuable insights, serving as a reference for future seismic optimization designs of large-scale oil storage tanks.

1. Mathematical Model Development

During the vibration of a storage tank, the fluids, including oil, inside experience movement and interact with the inner wall of the tank. This vibration induces an eddy current effect within the fluid, triggering a fluid-structure coupling reaction that can deform the tank and, in severe cases, result in tank failure.

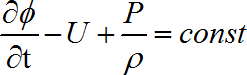

In the dynamic simulation of large vertical oil storage tanks, the establishment of a comprehensive mathematical model is imperative. This study employs fundamental equations from fluid dynamics, including the Euler equation, continuity equation, and Bernoulli equation. The derivation of the Bernoulli equation is presented as follows:

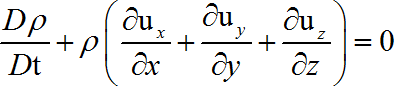

The continuity equation of this study is as follows:

As an advanced fluid mechanics software, Adina software used in this study has great advantages in simulating flow field, fluid-solid coupling field, solid mechanics, temperature field, fluid-acoustic coupling field, etc., and can better calculate the complex fluid-solid coupling and dynamic characteristics of large storage tanks in this study.

2. Design Parameters

To investigate the impact of varying storage depths and vibration levels on the performance of large vertical storage tanks, a three-dimensional simplified model was created in Solidworks based on the actual tank dimensions. Recognizing that certain structural components have minimal influence on simulation results, selective simplification was applied to reduce grid complexity and enhance computational efficiency.

This study focused on a 100,000 cubic meters large-scale oil vertical storage tank, with structural parameters outlined in Table 1. The tank, composed of 9 layers of steel plates, featured varying thicknesses for the edge plate (20 mm), the first level wall (34 mm), and the ninth level wall (12 mm). The tank's radius was 40 mm, height 21.8 mm, containing petroleum as the liquid. The maximum liquid storage depth was 20.2 mm, with a design temperature of 68℃.

3. Simulation Model Establishment

For the numerical simulation of large storage tanks with different storage depths and vibration levels, simulation models needed to be established and grids divided. Five liquid storage depths—40%, 50%, 60%, 70%, and 80% of the maximum depth—were selected. Simulation models for tanks with these depths were created and imported into CFD software for grid division. Distinct grid sizes were applied to different tank sections, ensuring accuracy and efficiency.

After grid division, the models were imported into Adina software for numerical simulation. Boundary conditions and vibration parameters were set, including four vibration grade parameters (5.5 degrees, 6.5 degrees, 7.5 degrees, and 8.5 degrees). The simulation involved incompressible fluid settings and the relevant parameters from Tables 1 and 2.

4. Analysis of Simulation Results

To comprehensively compare the effects of varying liquid depths and earthquake grades on oil storage tank performance, vertical stress and reliability index were introduced. Increased vertical stress signifies greater tank deformation, while a lower reliability index indicates an elevated risk of tank failure.

Analysis of vertical stress data revealed that, under various working conditions, higher liquid depths corresponded to increased vertical stress, heightened tank deformation, and a greater likelihood of failure. Particularly under design conditions (vibration level of 7.5 degrees), tanks with different storage depths exhibited noticeable external area deformation with increasing storage depth.

Examining the vertical stress trends for tanks with different storage depths and earthquake grades, it became evident that higher liquid depths led to greater vertical stress and lower reliability indices. The influence of earthquake grade on radial force was minimal at small reservoir depths but significantly escalated at 60%, potentially causing reliability index surpassing and tank failure. For tanks with the same liquid depth, higher earthquake levels resulted in greater vertical stress and lower reliability indices.

At a 60% liquid storage depth, vertical stress in tanks with varying earthquake grades notably increased, aligning with the observed trends.

Conclusion

To assess the seismic reliability of large-scale oil storage tanks, numerical simulations using Adina software and fluid-structure coupling theory were conducted. The study introduced vertical stress and reliability indexes to investigate the impact of different liquid depths and seismic grades on the performance of oil storage tanks, offering valuable insights for future research in this area. The key findings of this investigation are outlined below:

(1) Liquid depth and seismic grade exert a significant influence on the reliability of large vertical oil storage tanks.

(2) Under similar earthquake levels, higher liquid depths within the tank correspond to increased vertical stress in the large storage tank.

(3) At smaller liquid storage depths, the influence of earthquake grade on radial force is minimal. However, at a 60% liquid depth, the impact of earthquake grade on radial force significantly intensifies, potentially leading to reliability index surpassing and tank failure.

(4) With a constant liquid depth inside the tank, higher earthquake grades result in greater vertical stress in large vertical oil storage tanks and lower reliability indexes.

(5) To ensure the reliability of large oil storage tanks, it is recommended to design the liquid depth within the tanks to be less than 60%.

These conclusions provide essential guidance for enhancing the seismic reliability of large-scale oil storage tanks and serve as a foundation for future investigations in this field.