Mastering Stainless Steel Welding Materials for Pressure Vessel

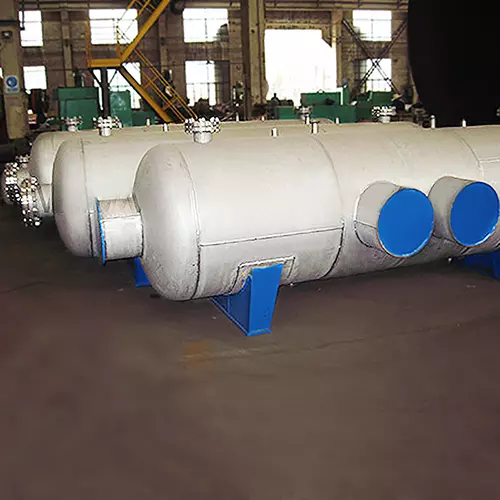

Choosing the right welding materials for stainless steel is a crucial task, with each type – austenitic, ferritic, and martensitic – having its unique considerations. In this exploration, we'll break down the essential principles guiding this selection process. Our goal is to understand how to create welds that not only match but often outperform the base metal in terms of corrosion resistance and mechanical strength. Join us in unraveling the specifics of welding material choices for each stainless steel type, simplifying the complexities to ensure sturdy and reliable welds in various applications, especially in the production of pressure vessels.

1. Austenitic Stainless Steel Welding Materials

The selection principles governing the choice of welding materials for austenitic stainless steel are multifaceted. The primary objective is to ensure that the corrosion resistance and mechanical properties of the weld metal closely align with or surpass those of the base metal, all while avoiding any instances of cracking. Crucially, the alloy composition of the welding material is expected to mirror that of the base material.

In the realm of corrosion-resistant austenitic stainless steels, a nuanced approach is required. It is generally advantageous for the weld metal to contain a certain proportion of ferrite. This not only enhances crack resistance but also fortifies corrosion resistance. However, there are exceptions, such as in the welding of urea equipment, where the presence of ferrite is prohibited due to its adverse effects on corrosion resistance. For austenitic steels designed for heat resistance, careful consideration must be given to controlling the ferrite content in the weld metal. Specifically, when these steels operate at elevated temperatures for prolonged periods, the ferrite content in the weld metal should not exceed 5%. Estimating the corresponding ferrite content is facilitated through the use of the Schaeffler diagram, relying on the chromium equivalent and nickel equivalent in the weld metal.

2. Ferritic Stainless Steel Welding Materials

The landscape of ferritic stainless steel welding materials can be categorized into three main types. The first comprises materials whose composition closely aligns with that of the base metal. The second involves the utilization of austenitic welding materials, while the third, although rare due to its exorbitant cost, encompasses nickel-based alloy materials.

When opting for a welding material equivalent to the base material, caution is warranted in situations where the degree of restraint is substantial, as this can lead to the generation of cracks. In such cases, post-weld heat treatment becomes a valuable tool for restoring corrosion resistance and enhancing joint plasticity.

Austenitic welding materials present an intriguing alternative, as they obviate the need for preheating and post-weld heat treatment. However, it is essential to remain vigilant, as sensitization of the heat-affected zone remains a concern for steels lacking stable elements. Commonly utilized chromium-nickel austenitic welding materials, such as 309 and 310, play a pivotal role in these scenarios. Additionally, for Cr17 steel, 308 type welding materials find applicability. Welding materials with higher alloy content emerge as beneficial in improving the plasticity of welded joints. Nevertheless, the choice of welding material necessitates careful consideration, particularly in corrosive media, where the corrosion resistance of the weld may significantly differ from that of the base metal.

3. Martensitic Stainless Steel Welding Materials

Martensitic stainless steel introduces a distinctive dimension to welding considerations, given its responsiveness to heat treatment. In ensuring performance requirements, especially for heat-resistant martensitic stainless steel, a critical factor is the close alignment of weld composition with the composition of the base metal.

To prevent cold cracking, austenitic welding materials can be employed, albeit with the acknowledgment that the weld strength may inherently be lower than that of the base metal. It becomes imperative to manage the hardening and brittleness of both the weld and the heat-affected zone, with the potential emergence of a temper softening zone.

In scenarios where preheating or heat treatment is challenging, the selection of austenitic microstructure welds becomes a strategic choice. The high plasticity and toughness of these welds alleviate weld stress, facilitating greater hydrogen dissolution and reducing the cold cracking tendency. However, the incongruity in material composition may introduce varying thermal expansion coefficients, potentially leading to shear stress and joint damage in environments with circulating temperatures.

For Cr13 martensitic steel, when an austenitic structure weld is not employed, adjustments in weld composition are limited. It generally mirrors that of the base material, with careful restrictions on harmful impurities such as S, P, and Si. Notably, Si's presence promotes the formation of coarse martensite in Cr13 martensitic steel welds, necessitating a reduction in C for improved hardenability. The introduction of elements like Ti, N, or Al refines grains and mitigates hardenability.

In the realm of multi-component alloyed Cr12-based martensitic heat-strength steel, primarily designed for heat resistance, austenitic welding materials are typically avoided. Instead, the emphasis is on closely matching the weld composition to that of the base metal. Attention must be paid to preventing the appearance of ferrite phases in the weld, particularly given the predominance of ferrite elements (Mo, Nb, W, V, etc.) in Cr13-based martensitic heat-strength steel. Achieving a uniformly martensitic organization demands a delicate balance with austenite elements, including appropriate levels of C, Ni, Mn, and N. Martensitic stainless steels, due to their heightened susceptibility to cold cracking, demand stringent adherence to low hydrogen and ultra-low hydrogen conditions, a critical consideration in the selection of welding materials.