LNG Storage Tanks: Evaporation, Stratification & Roll-Over

On this page

Liquefied Natural Gas (LNG) is a cryogenic liquid. It is widely used for energy storage and transportation. However, due to its low temperature, LNG is affected by external heat in storage tanks. This heat can cause evaporation, stratification, and roll-over phenomena. These phenomena can reduce the efficiency of LNG storage and transport. They can also cause serious safety risks. Therefore, it is important to understand the causes of evaporation and stratification in LNG storage tanks and take preventive measures.

Evaporation and Stratification in LNG Cryogenic Storage Tanks

LNG is a low-temperature liquid. During storage, it can be affected by external heat. LNG is made up of hydrocarbons with different boiling points. When heat enters the tank, the lower boiling components (like methane) evaporate first. The higher boiling components (like ethane and propane) evaporate more slowly. Over time, the composition of LNG in the tank changes. The proportion of heavier hydrocarbons increases.

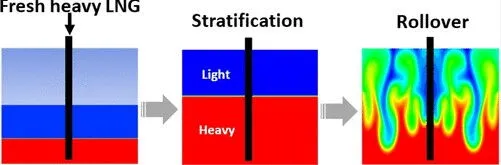

Normally, LNG has a low evaporation rate. The evaporated gas can be re-liquefied or sent to the city gas network. However, as the LNG level decreases in the tank, new LNG must be added. The physical properties of LNG, such as density and vapor pressure, depend on temperature. When new LNG is added to the tank, the density and temperature differences between the new and old LNG can cause stratification.

Stratification happens when layers of LNG with different temperatures and densities form in the tank. The heat exchange and mass transfer between these layers can cause mixing over time. However, in some conditions, the evaporation rate can suddenly increase, causing roll-over.

Causes of LNG Storage Tank Roll-Over

Roll-over in LNG storage tanks happens due to rapid evaporation. When stratification occurs, the upper layer of LNG exerts static pressure on the lower layers. This prevents external heat from reaching the lower layers. As a result, the lower layers become supersaturated. Without proper control, this supersaturated LNG can evaporate quickly.

When the density of the upper LNG layer is higher than that of the lower layer, the upper LNG will sink. This causes the lower LNG to rise and evaporate rapidly. If the evaporation rate increases too quickly, it can raise the pressure in the tank. This can lead to equipment failure or safety incidents.

For example, when LNG is delivered from a ship, it is usually slightly warmer than the LNG in the tank. The temperature difference between the new LNG and the remaining LNG is small, so the LNG does not mix well. Stratification occurs, with the upper layer having colder, less dense LNG and the lower layer having warmer, denser LNG. Over time, the methane in the upper layer evaporates. This increases its density. Once the upper layer becomes denser than the lower layer, the lower layer LNG rises and evaporates quickly. This rapid evaporation raises the pressure in the tank. If the pressure is not released in time, a dangerous situation may occur.

Risks of LNG Storage Tank Roll-Over

Roll-over in LNG storage tanks can cause several safety risks.

Overpressure: The rapid evaporation from roll-over increases the gas pressure in the tank. If the pressure exceeds the tank's design limit, it can cause damage or an explosion.

Tank Rupture: LNG expands significantly at low temperatures. If the internal gas pressure is too high, it can cause the tank to deform or even rupture.

Gas Leaks and Fire Risks: When LNG evaporates quickly, it creates a large amount of gas. If this gas mixes with air and reaches a certain concentration, it can cause a fire or explosion.

Preventive Measures for LNG Tank Roll-Over

To prevent roll-over in LNG storage tanks, effective measures must be taken. These measures control temperature, pressure, and density changes inside the tank. Some of the key preventive measures are as follows.

1. Optimizing the Feeding Method

Light LNG should be injected from the bottom of the tank, or heavy LNG should be injected from the top. Alternatively, a combination of both methods can be used. This helps avoid stratification. The goal is to ensure that the new LNG mixes well with the remaining LNG.

2. Real-Time Density Monitoring

Automatic density meters should be installed in the tank. These meters will monitor density changes in different layers of LNG. This ensures the LNG is mixed evenly and prevents roll-over caused by excessive density differences.

3. Liquid Circulation

Using pumps to circulate the LNG from the bottom to the top of the tank helps prevent stratification. Circulation promotes mixing between the different layers, preventing supersaturation and rapid evaporation.

4. Vaporization Rate Monitoring

The vaporization rate should be monitored to prevent rapid evaporation. Keeping the nitrogen content of the LNG below 1% can help slow down the evaporation rate. Nitrogen is an inert gas that reduces evaporation.

Preventing LNG Tank Overflow and Leaks

LNG storage tanks must be designed to handle overflow and leakage risks during storage and unloading. LNG leaks or spills can pose serious environmental and safety risks. Therefore, preventive measures must be in place.

1. Leakage Protection Facilities

Effective leakage protection should be installed around the tank. This includes bund walls, guardrails, and liquid storage pits to prevent LNG from spreading. Leak-prone areas like valves and joints should have barriers and catch pans to collect any LNG that leaks. The LNG should then be directed into the storage pits.

2. Underground Storage Tanks

Large LNG tanks should be built underground. This reduces the risk of leakage and ensures that the LNG surface is lower than the surrounding ground, minimizing environmental impacts in case of leakage.

3. Storage Capacity Requirements

The storage pits should be designed to hold the maximum capacity of LNG in the tank. The pits must also account for seasonal factors, such as snow accumulation. They should be large enough to handle any potential leaks.

Conclusion

To ensure the safe and stable operation of LNG storage tanks, several preventive measures should be taken. These include optimizing the feeding method, monitoring density changes in real time, improving liquid circulation, and controlling the vaporization rate. In addition, leakage protection facilities and proper tank design are essential for environmental safety and emergency response. By using a comprehensive approach, LNG storage tanks can be protected from roll-over and leakage, ensuring safe and efficient energy storage and transportation.