Introducing Internal Components of Three Phase Separators

On this page

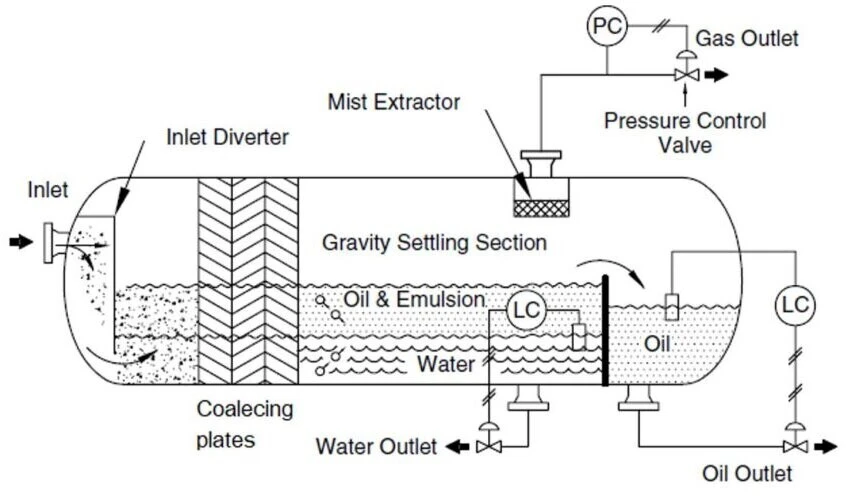

In the oil and gas industry, three-phase separators stand as crucial equipment for effectively separating crude oil, natural gas, and water into their respective phases, meeting the demands of processing operations. The internal components of the separator vessel are intricately designed, and below, we delve deeper into their functions and roles.

1. Inlet Components

Inlet components play a pivotal role in ensuring the smooth entry of mixed-phase fluids into the separator while effectively separating the gas and liquid phases upon entry. Different designs of inlet components can achieve this goal based on variations in fluid properties and flow rates. For instance, swirl elements utilize vortex action to separate gas from liquid.

2. Baffle Elements

Fluid entering the separator may bring about intense vortices and turbulence, which can affect the gravity separation process inside the separator. The purpose of baffle elements is to reduce these turbulences, enabling the fluid to flow more stably within the vessel, thereby providing favorable conditions for subsequent separation.

3. Coalescing Elements

Coalescing elements are designed to address the issue of droplet coalescence. By providing the appropriate surface area and flow paths, these elements aid in the rapid aggregation of droplets in the liquid phase, facilitating more effective separation.

4. Vortex Suppression Elements

During the outflow of the liquid phase, vortex or whirlpool formations often occur, leading to the entrainment of gas into the liquid outflow. Vortex suppression elements are designed to mitigate such occurrences, ensuring the effectiveness of the separation process. They typically employ specialized shapes or structures to prevent vortex formation.

5. Distillation Wells

Distillation wells not only stabilize the fluid level but also help in removing bubbles or impurities to some extent, ensuring the proper functioning of liquid discharge devices. They are often used in conjunction with liquid level control devices to achieve accurate level control.

6. Sand Removal Elements

Considering the presence of solid particles in the fluid, sand removal elements are designed to prevent the accumulation of these particles at the bottom of the separator, which could otherwise impede the normal operation of the equipment. They often employ special structures or materials to prevent the formation of deposits.

7. Mist Elimination Elements

The role of mist elimination elements is to remove entrained tiny liquid droplets in the gas-liquid flow, ensuring that the output gas phase is clean. They typically utilize grids, fibers, or special-shaped structures to achieve effective mist removal.

Through a comprehensive understanding of these internal components, we gain insights into the working principles and optimized designs of three-phase separators. In practical applications, suitable combinations of components can be selected based on the varying properties of oil and gas and the requirements of processing operations to achieve optimal separation efficiency.