Main Structural Types of Pressure Vessels and Their Classification

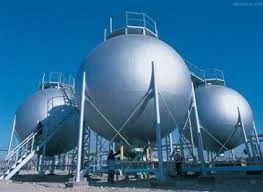

1. What are the primary structural types of pressure vessels? Pressure vessels come in various structural forms, including spherical, cylindrical, box-shaped, and conical vessels. 2. What role do reaction pressure vessels play in production, and what are some common types? Reaction pressure vessels are essential for conducting physical and chemical reactions in the production process. Examples include reaction kettles, decomposition kettles, vulcanization tanks, decomposition towers, polymerization...