What Is a Heat Exchanger and How Is Its Transfer Area Determined?

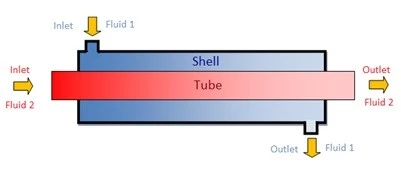

What is a heat exchanger? A heat exchanger is a device designed to transfer heat from a hotter fluid to a cooler fluid. What is the heat transfer area of a heat exchanger? The heat transfer area is calculated as the outer surface area of the tube, considering the outer diameter and deducting the length that extends into the tube sheet. In U-tube heat exchangers, the area of the U-shaped bend is typically excluded.