How to Mitigate Vibration Issues in Heat Exchanger Tubes

On this page

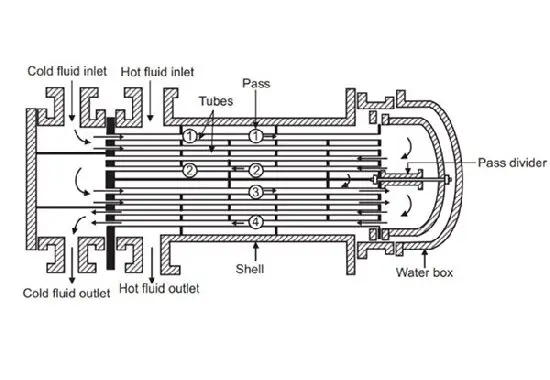

In modern industrial applications, heat exchangers serve as critical equipment for the heating and cooling of various fluids. However, issues related to the vibration of heat exchanger tubes can lead to decreased performance and even failure of the equipment. These vibrations not only potentially shorten the lifespan of the equipment but also result in operational interruptions and increased maintenance costs. Understanding the causes, impacts, and preventive measures for vibrations is crucial for ensuring the stability and reliability of heat exchangers.

Causes of Vibration

The vibration of heat exchanger tubes is generally caused by two main factors that can lead to reduced performance or equipment failure in industrial settings.

1. External Excitation Sources

Reciprocating Mechanical Pulsations: Pulsations from reciprocating mechanical equipment can transmit through supporting components or connecting pipes to the heat exchanger tubes, causing vibrations. These vibrations are typically due to periodic airflow changes caused by mechanical operations, which can affect the stability of the heat exchanger.

Vibration from Supporting Components or Connecting Pipes: External excitation sources can transfer vibrations through supporting components or connecting pipes to the heat exchanger tubes, resulting in tube vibrations. Such vibrations may arise from structural transmission effects in the equipment, such as unstable foundations or inadequate equipment securing.

2. Fluid Flow-Induced Excitation

Tube Side Flow Excitation: At normal flow velocities, tube side flow-induced vibrations are relatively minor and usually do not significantly impact the heat exchanger. However, when the flow velocity is significantly higher than normal, the impact of tube side flow excitation becomes more pronounced and may require special attention.

Shell Side Flow Excitation: Vibrations caused by shell-side fluid flow can result in larger amplitudes, posing the greatest risk to heat exchanger tubes. Research indicates that when the excitation frequency of the fluid approaches the natural frequency of the heat exchanger components, the vibration amplitude can significantly increase, leading to severe vibration damage.

Types of Vibration Damage

Vibration-induced damage to heat exchanger tubes primarily includes the following two types, which can lead to decreased equipment performance and long-term damage to the piping system.

1. Tube Wear

Inter-Tube Wear: In cases of large amplitude vibrations, tubes may contact each other, causing wear and forming diamond-shaped wear marks. This primarily occurs at the maximum displacement location, i.e., the mid-span. Thermal expansion of the tubes can also increase the likelihood of wear, as thermal deformation enlarges the contact area between tubes.

Tube and Support Plate Wear: Vibrations can cause relative movement between the tubes and support plates, gradually wearing down the tube walls and potentially leading to perforation. This wear is particularly pronounced when there is incomplete alignment between the support plates and tubes.

Baffle Cutting Wear: The holes in baffles are typically 0.8–1.2 mm larger than the tube's outer diameter. Vibration may lead to cutting or breaking of the tubes by the baffles, especially when the baffle material is thin and hard.

Cutting Action at Tube Outlets: Sharp edges at the tube outlets can cut or damage the tubes, leading to wear or other damage.

2. Tube Fatigue Failure

Cyclic Alternating Stresses: Cyclic vibrations, including resonance or microvibrations, subject the tubes to repeated bending stresses. Prolonged exposure to intense cyclic stresses can lead to fatigue cracks in high-stress areas, ultimately causing tube failure.

Locations of Vibration Damage

Mid-Span of Support Spans: Tubes colliding at the mid-span of support spans can create noticeable wear marks.

Notch Adjacent to Baffles: Collisions between tubes and baffles can cause localized wear.

Within Baffle Holes: Edges of baffle holes may saw or collide with the tubes, potentially leading to tube rupture in severe cases.

Expansion of Fine Cracks: Existing fine cracks or defects may gradually expand due to vibrations, leading to tube failure.

Preventive Measures

To effectively reduce tube vibrations and their potential damage, the following preventive measures can be implemented:

1. Reduce Local High-Speed Fluid Flow

Lower Shell-Side Flow Velocity: Avoid resonance excitation by decreasing shell-side flow velocity. If operational conditions cannot be altered, design anti-impingement plates, flow diffusers, or liquid outlet distributors at the heat exchanger's inlet and outlet to reduce fluid pulsation values.

2. Alter the Natural Frequency of Heat Exchange Components

Reduce Span: The natural frequency of the tubes is inversely proportional to the square of the span; reducing the span can significantly increase the natural frequency. For example, reducing the span by 20% can raise the natural frequency by 50%.

Increase Support: For U-tube bundles, adding strips or inserting rods or plates between tubes can increase the natural frequency.

Modify Baffle Design: Utilize designs such as rod-type or spiral baffles to improve tube support conditions and reduce vibration effects.

By implementing these preventive measures, the vibration issues in heat exchanger tubes can be significantly reduced, enhancing the operational stability of the equipment and extending its service life.

In summary, the causes of heat exchanger tube vibrations are diverse, ranging from external excitation sources to fluid flow-induced excitation. Wear and fatigue failure are the primary types of damage caused by vibrations, posing serious threats to equipment stability. Through measures such as reducing local flow velocities and modifying component natural frequencies, the impact of vibrations on heat exchangers can be effectively mitigated, improving operational efficiency and longevity.