Heat Exchangers: Direct, Indirect, and Regenerative Types

On this page

In many industrial and commercial processes, heat transfer is crucial. Heat exchangers are devices designed for the efficient transfer of heat, and they are mainly categorized into three types based on their operating principles: direct contact heat exchangers, indirect heat exchangers, and regenerative heat exchangers. Each type has its unique advantages and applicable scenarios. This article will provide an overview of the working principles, main types, and application areas of these three heat exchangers to help you better understand their roles in practical use.

Direct Contact Heat Exchangers

Direct contact heat exchangers operate by allowing two fluids to come into direct contact, enabling straightforward and efficient heat exchange. This type of exchanger utilizes the direct contact between a hot fluid and a cold fluid to achieve high-efficiency heat transfer. Despite their simple structure, direct contact heat exchangers play a significant role in many industries due to their unique heat exchange method. However, this design also presents some potential challenges and limitations that need careful consideration in practical applications.

1. Working Principle

Direct contact heat exchangers achieve heat transfer by bringing two fluids of different temperatures into direct contact. The hot fluid is sprayed in a mist form through nozzles or a film tower, where it meets the cold fluid. Heat is directly transferred between the hot and cold fluids, causing the cold fluid to warm up and the hot fluid to cool down. The process includes:

Spraying: The hot fluid is sprayed through nozzles to form droplets.

Contact Exchange: The cold fluid contacts the droplets through nozzles, absorbing heat.

Result: The hot fluid cools down, and the cold fluid warms up.

2. Key Advantages

Efficient Heat Transfer: Direct contact allows for higher heat exchange efficiency.

Low Energy Loss: The absence of physical barriers reduces energy loss between fluids.

Cost-Effective: Simple design leads to lower production and maintenance costs.

3. Main Disadvantages

Chemical Reaction Risk: Direct contact between hot and cold fluids may trigger chemical reactions, leading to equipment corrosion or damage.

Fluid Suitability: Mainly suitable for low-viscosity fluids like water and air; not suitable for higher viscosity fluids.

Environmental and Safety Issues: Special care is needed to prevent contamination and environmental impact.

Direct contact heat exchangers are widely used in the chemical and pharmaceutical industries for thermal energy exchange, such as in reactors and dryers; for cooling water treatment; and in oxygen generators, pickling, and refrigeration equipment.

Indirect Heat Exchangers

Compared to direct contact heat exchangers, indirect heat exchangers use a solid wall to separate the hot and cold fluids, ensuring there is no direct contact between them. This type of heat exchanger is particularly effective in handling fluids that are high-temperature, high-pressure, or have special requirements. They transfer heat through the wall and offer a wide range of applications and diverse designs.

1. Working Principle

Indirect heat exchangers separate hot and cold fluids with solid barriers, transferring heat through these barriers. Common types of indirect heat exchangers include:

Tubular Heat Exchangers: Consist of a bundle of parallel tubes where two fluids flow inside and outside the tubes. Heat is transferred through the tube walls from one fluid to another. Suitable for various pressure and temperature conditions, these are widely used in petroleum, chemical, and energy industries.

Plate Heat Exchangers: Composed of multiple corrugated metal plates stacked together, forming several thin rectangular channels. Fluids flow through these channels to exchange heat, offering high heat transfer efficiency and compact design. Plate heat exchangers are particularly suitable for liquid-liquid and liquid-gas heat exchange and are widely used in the pharmaceutical, food processing, and chemical industries.

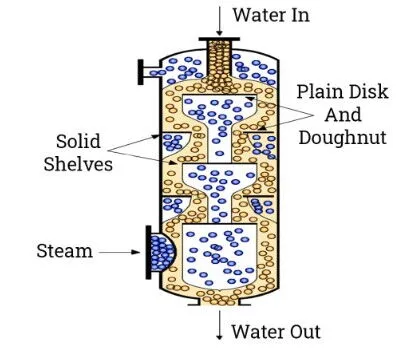

Jacketed Heat Exchangers: A jacket is installed on the outer wall of a vessel, and heating or cooling fluids flow through the jacket to transfer heat. The structure is simple, but due to the jacket’s limitation by the vessel wall, the heat transfer coefficient is relatively low. Installing stirrers or enhancing turbulence can improve heat transfer efficiency.

Immersion Coil Heat Exchangers: Comprise coiled metal tubes immersed in the liquid inside a vessel. The advantages include simple structure, high pressure resistance, and corrosion-resistant materials. The downside is lower turbulence of the liquid, leading to a lower heat transfer coefficient, which can be improved by installing stirrers.

Spray Heat Exchangers: Hot fluids flow inside tubes, while cooling water is uniformly sprayed over the tubes through a spraying device. Utilizing the turbulence effect of liquid film and evaporative cooling, spray heat exchangers enhance heat transfer and are widely used in air cooling and water treatment.

Double-Pipe Heat Exchangers: Consist of concentric pipes of different diameters, with fluids flowing inside the inner pipe and in the annulus between the pipes. These are suitable for high-pressure applications requiring high heat transfer coefficients, such as ultra-high-pressure production processes like high-pressure polyethylene production.

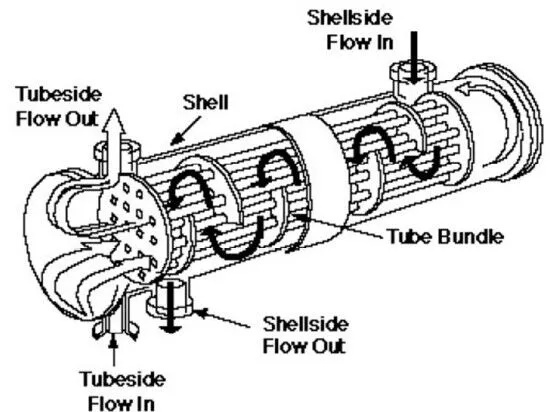

Shell and Tube Heat Exchangers: The most common type of indirect heat exchanger, consisting of a shell, tube bundle, tube sheet, and headers. Fluids flow inside the tubes and within the shell, transferring heat through the tube walls. Shell and tube heat exchangers are widely used in the chemical, petroleum, and pharmaceutical industries.

2. Pros and Cons

Wide Application: Suitable for various fluids and different process conditions.

Flexible Design: Can adjust tube bundles, plates, etc., according to needs to improve heat exchange efficiency.

Complex Maintenance: Tubular and plate heat exchangers may be complex in cleaning and maintenance.

Space Requirements: Some types, like shell and tube heat exchangers, occupy considerable space.

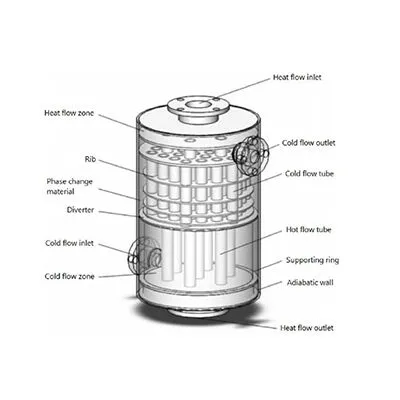

Regenerative Heat Exchangers

Regenerative heat exchangers differ from direct and indirect heat exchangers in that they store heat to balance the supply and demand of thermal energy. This type of heat exchanger can provide stable heat exchange in processes with fluctuating loads, effectively improving the system's thermal energy utilization efficiency. Regenerative heat exchangers are widely used in situations where it is necessary to balance thermal loads at different times, such as in industrial furnaces and power plants.

1. Working Principle

Regenerative heat exchangers achieve heat transfer by temporarily storing heat. The process includes:

Heating Cycle: Hot gas flows through the packing material of the regenerator, storing heat in the packing and lowering the gas temperature.

Cooling Cycle: The flow direction switches, and cold fluid flows through the regenerator, absorbing heat from the packing material, which releases heat to the cold fluid during the cooling cycle.

2. Main Forms

Fixed Bed Type: Typically requires two beds operating alternately, with one bed in the heating cycle and the other in the cooling cycle. The flow direction is switched by a valve, suitable for applications requiring continuous heat transfer.

Rotary Type: Hot and cold fluids continuously flow through rotating cylindrical packing, or the packing remains stationary while the hot and cold fluids rotate alternately. Rotary regenerative heat exchangers do not require two storage chambers or switching valves, making them suitable for continuous heat exchange applications.

3. Advantages

High Energy Utilization Efficiency: Can use waste heat for preheating, improving energy efficiency.

Broad Application Range: Used in various industrial processes such as metal reduction, heat treatment, and glass furnaces.

Regenerative heat exchangers are widely applied in preheating combustion air, steel manufacturing, power plant boilers, high-temperature air combustion devices, and more. Early applications were mainly concentrated in hot blast stoves in the steel industry and rotary air preheaters in power plants.

Direct contact, indirect, and regenerative heat exchangers each have distinct characteristics and application scenarios. Direct contact heat exchangers are highly efficient and simple in structure, widely used in the chemical and pharmaceutical industries; indirect heat exchangers are widely applied in liquid and gas heat exchange due to their high-efficiency heat transfer capability; regenerative heat exchangers are suitable for intermittent heat exchange applications, such as metal smelting and power generation. Understanding the basic features and uses of these heat exchangers will help you choose the most appropriate equipment for your needs, improving heat exchange efficiency and reducing costs.