Heat Exchanger Cleaning Techniques

What are the maintenance standards for heat exchangers?

(1) During the operation, pulling, loading, transportation, and hoisting of heat exchanger bundles, avoid directly tying the exposed wire rope to prevent damage to the heat exchange tubes.

(2) Clean the internal and external structures of the tube bundle.

(3) Process gaskets as a whole when tube boxes and floating heads have partitions to ensure effective sealing without defects.

(4) Tube bundle plugging: Limit the number of blocked pipes within 10% of the total, with flexibility within the allowable technological index.

(5) Ensure that parts meet technical requirements and provide material quality certificates.

(6) Replace heat pipes as needed.

(7) Follow GB1511999 or design drawings for overall bundle replacement.

(8) Conduct shell repairs according to SHS01004-2004 "Rule of Maintenance and Repair of Pressure Vessels."

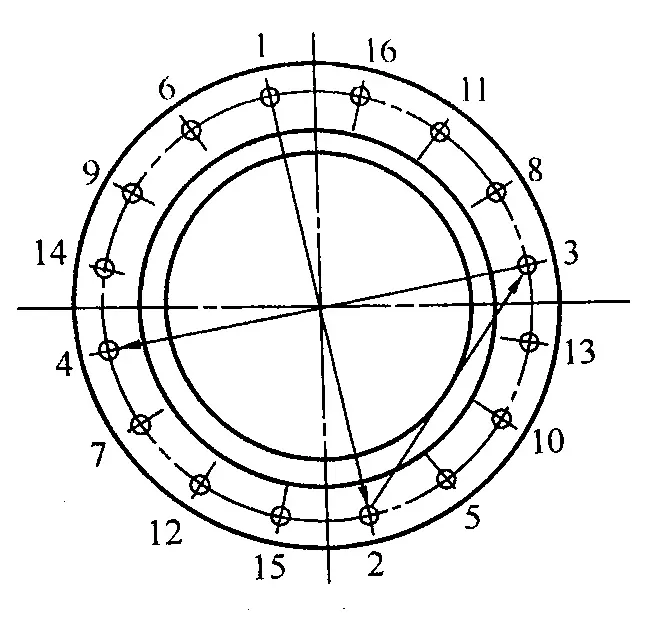

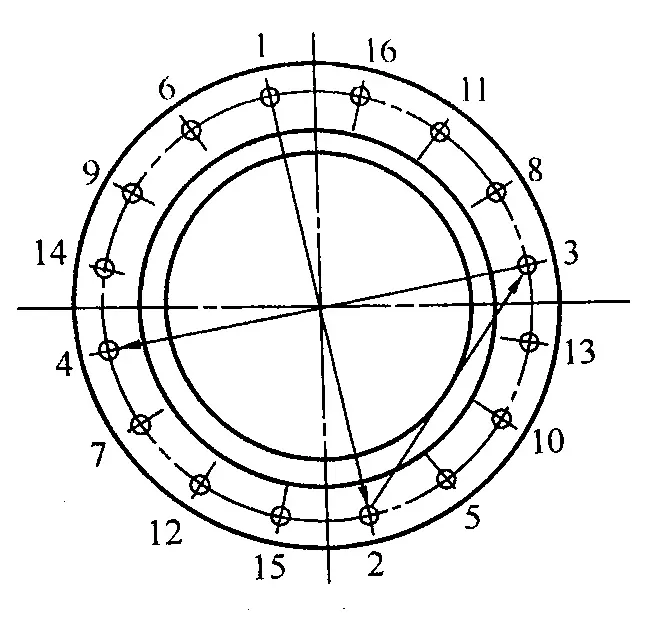

(9) Choose replacement sealing gaskets based on design requirements.

(10) When replacing bolts and nuts, follow design requirements, tighten bolts in the specified order, and use appropriate thread lubricant or anti-seize compound.

Why is regular cleaning essential for heat exchangers?

Over time, heat exchangers accumulate dirt on the heat transfer wall, increasing thermal resistance and reducing the K value, impacting efficiency. Since dirt's thermal resistance surpasses the wall surface, regular cleaning is crucial post-operation.

Cleaning methods for heat exchangers:

Air sweeping, water washing, steam washing, chemical cleaning, and mechanical cleaning are common methods.

Impact of heat exchange tube surface structure:

Specially designed surfaces like finned tubes, nail head tubes, and threaded tubes increase heat transfer area and induce turbulence, enhancing overall heat exchange efficiency compared to smooth tubes.

Common methods for descaling heat exchange tube surfaces:

Manual brazing descaling, mechanical descaling, pressure water descaling, chemical descaling, ultrasonic descaling, etc.

Methods to prevent scale on heat exchange tube surfaces:

(1) Nickel and phosphorus plating

(2) Chemical and 847 coatings

(3) Installing ultrasonic scale inhibitors in cold water pipelines.

(1) During the operation, pulling, loading, transportation, and hoisting of heat exchanger bundles, avoid directly tying the exposed wire rope to prevent damage to the heat exchange tubes.

(2) Clean the internal and external structures of the tube bundle.

(3) Process gaskets as a whole when tube boxes and floating heads have partitions to ensure effective sealing without defects.

(4) Tube bundle plugging: Limit the number of blocked pipes within 10% of the total, with flexibility within the allowable technological index.

(5) Ensure that parts meet technical requirements and provide material quality certificates.

(6) Replace heat pipes as needed.

(7) Follow GB1511999 or design drawings for overall bundle replacement.

(8) Conduct shell repairs according to SHS01004-2004 "Rule of Maintenance and Repair of Pressure Vessels."

(9) Choose replacement sealing gaskets based on design requirements.

(10) When replacing bolts and nuts, follow design requirements, tighten bolts in the specified order, and use appropriate thread lubricant or anti-seize compound.

Why is regular cleaning essential for heat exchangers?

Over time, heat exchangers accumulate dirt on the heat transfer wall, increasing thermal resistance and reducing the K value, impacting efficiency. Since dirt's thermal resistance surpasses the wall surface, regular cleaning is crucial post-operation.

Cleaning methods for heat exchangers:

Air sweeping, water washing, steam washing, chemical cleaning, and mechanical cleaning are common methods.

Impact of heat exchange tube surface structure:

Specially designed surfaces like finned tubes, nail head tubes, and threaded tubes increase heat transfer area and induce turbulence, enhancing overall heat exchange efficiency compared to smooth tubes.

Common methods for descaling heat exchange tube surfaces:

Manual brazing descaling, mechanical descaling, pressure water descaling, chemical descaling, ultrasonic descaling, etc.

Methods to prevent scale on heat exchange tube surfaces:

(1) Nickel and phosphorus plating

(2) Chemical and 847 coatings

(3) Installing ultrasonic scale inhibitors in cold water pipelines.