Establishing the Maintenance Interval for Shell and Tube Heat Exchangers

How to establish the maintenance schedule for shell and tube heat exchangers?

In alignment with the "Pressure Vessel Safety Technical Supervision Regulations" and considering the operational conditions of the enterprise, a comprehensive assessment suggests a typical maintenance cycle of 2 to 3 years.

What are the maintenance criteria for shell and tube heat exchangers?

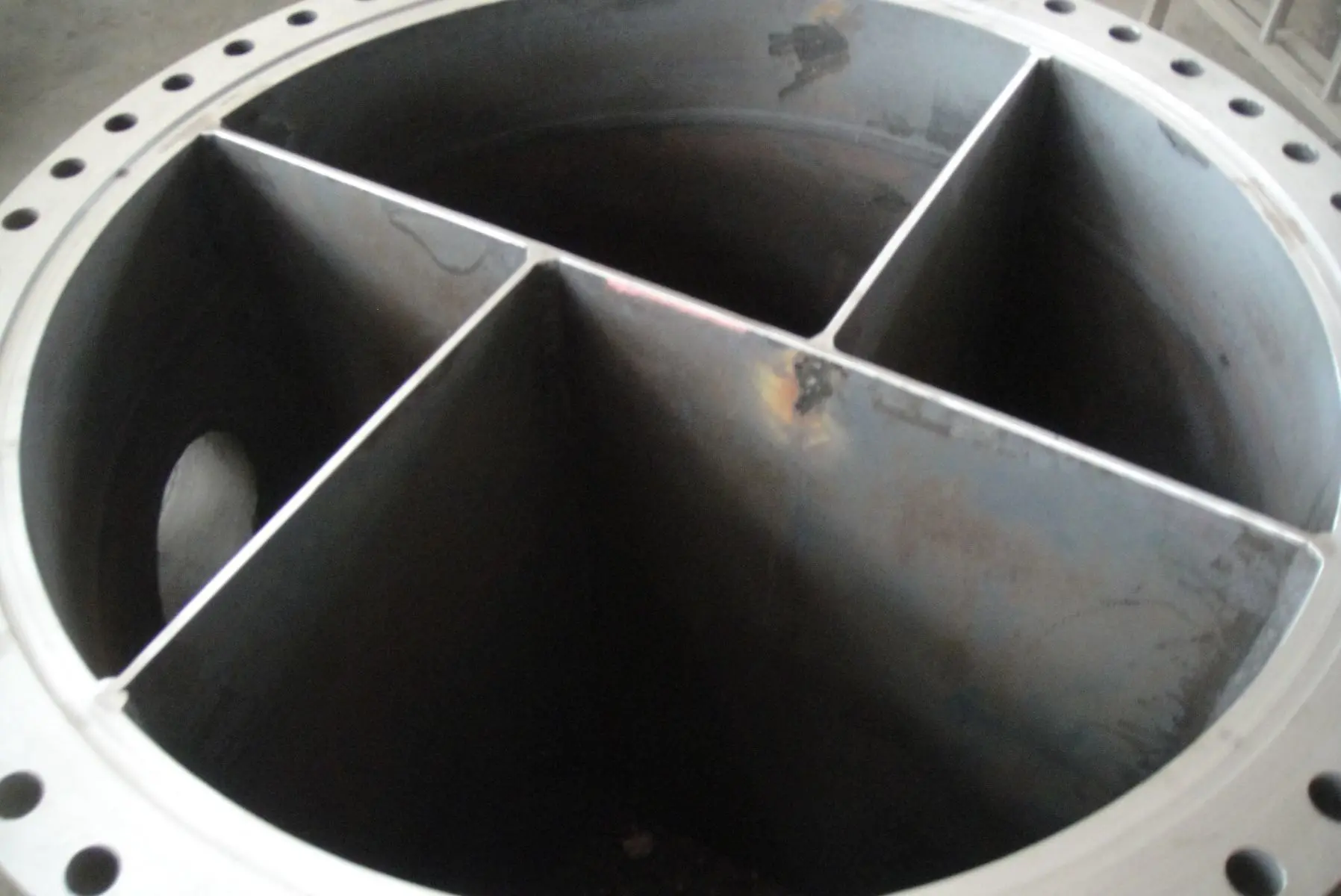

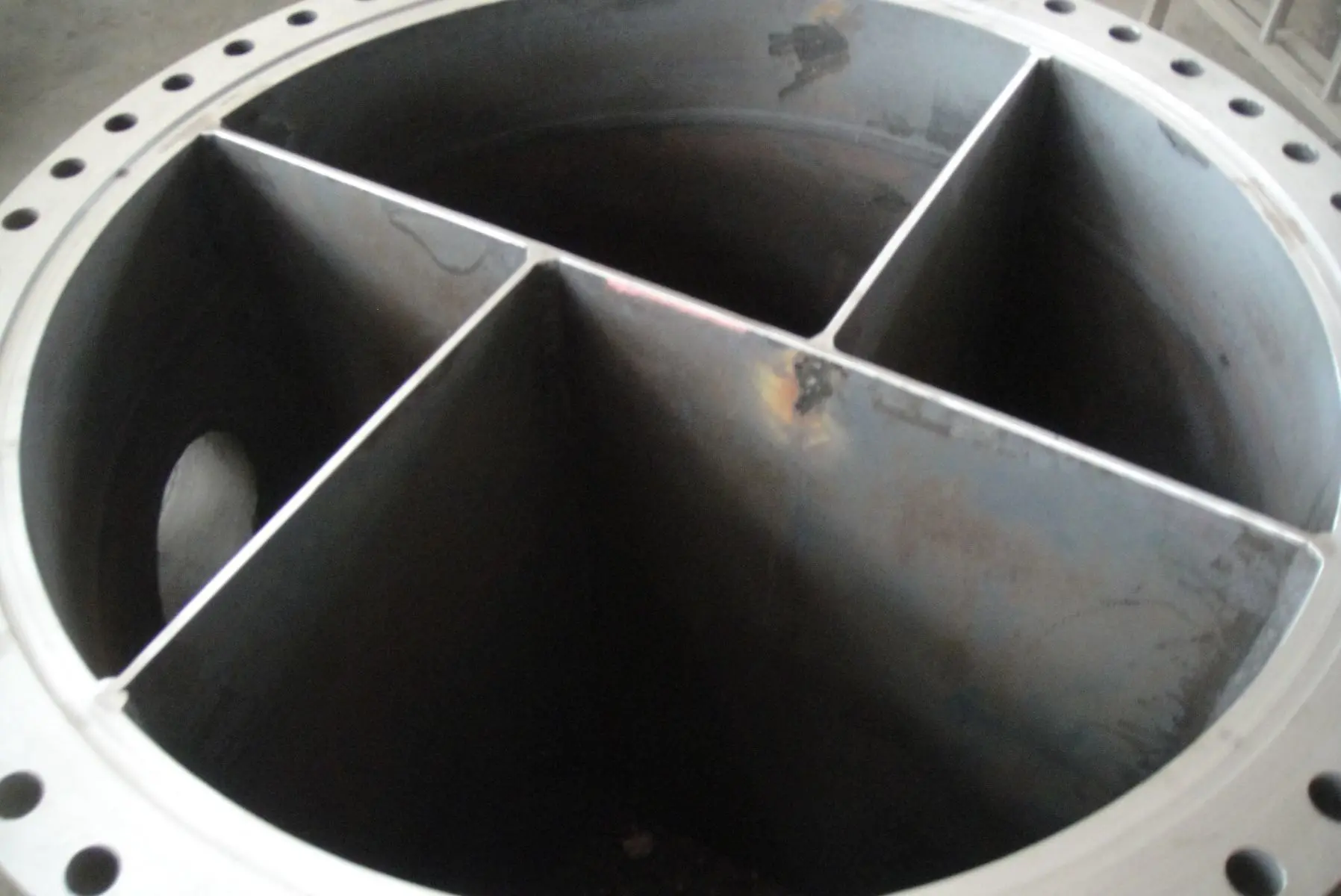

(1) Extraction of the core, cleaning of the tube bundle, and shell.

(2) Execution of welding and expansion procedures for the tube bundle, including the replacement of individual tubes.

(3) Inspection of the tube box and its internal components, floating head cover, hook ring, outer head cover, nozzle, and their sealing surfaces. Replacement of gaskets and pressure testing.

(4) Replacement of selected bolts and nuts.

(5) Application of thermal insulation to the shell, along with repairs and corrosion protection.

(6) Substitution of either the tube bundle or the entire shell.

In alignment with the "Pressure Vessel Safety Technical Supervision Regulations" and considering the operational conditions of the enterprise, a comprehensive assessment suggests a typical maintenance cycle of 2 to 3 years.

What are the maintenance criteria for shell and tube heat exchangers?

(1) Extraction of the core, cleaning of the tube bundle, and shell.

(2) Execution of welding and expansion procedures for the tube bundle, including the replacement of individual tubes.

(3) Inspection of the tube box and its internal components, floating head cover, hook ring, outer head cover, nozzle, and their sealing surfaces. Replacement of gaskets and pressure testing.

(4) Replacement of selected bolts and nuts.

(5) Application of thermal insulation to the shell, along with repairs and corrosion protection.

(6) Substitution of either the tube bundle or the entire shell.