Enhancing Surge Tank Performance in Oilfield Operations

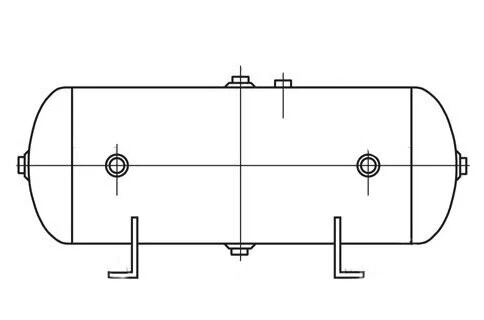

The surge tank is essential in oilfield production, facilitating oil and gas separation, storage, and system balance for safe transportation. Also known as a horizontal separator, it offers higher processing capacity, making it prevalent in booster, transfer, joint, and centralized processing stations. Its proper functioning is critical for smooth operations. Yet, surge tanks often encounter various malfunctions, which we'll explore along with solutions.

1. Pressure Relief Measures

When the internal pressure of the surge tank exceeds the set pressure of the safety valve, it automatically releases to relieve overpressure. This may occur due to excessive liquid inflow or improper system operation. In such cases, immediate shutdown is necessary, followed by procedural handling. Additionally, opening bypass valves and closing inlet and outlet valves facilitate further actions.

2. Liquid Level Monitoring

The high and low liquid level alarm system in the surge tank is vital for ensuring safe operation. However, malfunctions such as jammed or leaking floats and non-closing electrical contacts may render the alarm system ineffective. Immediate shutdown, followed by float inspection and replacement, along with maintenance of the high and low liquid level alarm devices, is essential.

3. Pressure Stability Checks

Excessive pressure drop in the surge tank may result from excessively opened gas relief valves, inadequate liquid levels inside the tank, or leaks in pipelines or containers. Immediate closure of gas relief valves, cessation of oil transfer, and thorough inspection and repair of leakage points are necessary steps in addressing this issue.

4. Efficient Liquid Discharge

Slow discharge of liquid may be caused by insufficient opening of outlet valves, inadequate tank pressure, excessive sedimentation at the bottom of the tank, or insufficient pumping capacity. Addressing this issue requires thorough investigation and corresponding measures such as enlarging outlet valves, halting oil transfer, regular drainage, and sediment removal.

5. Pipeline Blockage Prevention

Freezing blockage in the gas outlet pipeline may impede transportation, primarily caused by condensation freezing in the pipeline or prolonged shutdown without flushing the gas pipeline. Addressing this requires immediate shutdown, thawing of the pipeline, and strict adherence to surge tank shutdown procedures.

6. Temperature Regulation

Rapid decrease in oil temperature may result from corrosion and leakage of internal heating coils or insufficient circulation of hot water in the heating pipeline. To address this, immediate shutdown for heating coil repair and inspection of heating loop circulation are necessary, along with increasing the heat load as needed.

In conclusion, the surge tank is indispensable in oilfield production, and its proper operation is crucial for the safe and stable transportation of oil and gas. Therefore, establishing a robust monitoring and maintenance mechanism is essential to ensure the reliable operation of surge tank equipment. Only through continuous attention and resolution of potential malfunctions and issues can we guarantee smooth oilfield production and make greater contributions to the energy industry's development.