What are Corrugated Tube Heat Exchangers?

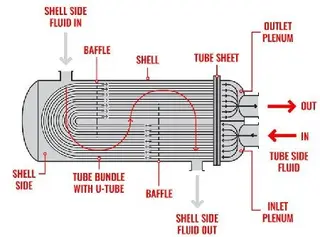

The corrugated tube heat exchanger is an innovative heat exchange device that combines enhanced heat transfer and mechanical principles. It is widely used in industrial fields. Based on the design of traditional heat exchangers, it has been optimized to retain the advantages of traditional tubular heat exchangers, such as strength, durability, safety, and reliability, while overcoming their shortcomings, such as poor heat transfer capacity and easy scaling. Through the special design of the corrugated...