Four Inquiries Regarding Heat Exchangers

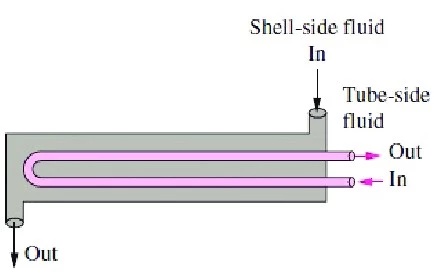

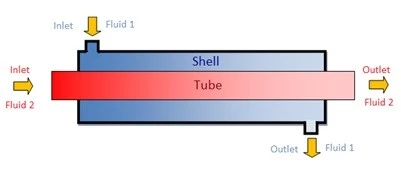

1. How to Compare the Indicators of Heat Exchange Equipment? Different types of heat exchange equipment can be compared based on factors such as high efficiency, compact structure, material savings, low pressure drop, reliable structure, low manufacturing cost, easy installation, maintenance, and long service life. 2. How to Describe the Model of a Heat Exchanger? DN represents the nominal diameter of the heat exchanger, indicating the inner diameter of the rolled cylinder and the outer diameter...