Exploring Liquid Oxygen Tanks for Enhanced Safety and Performance

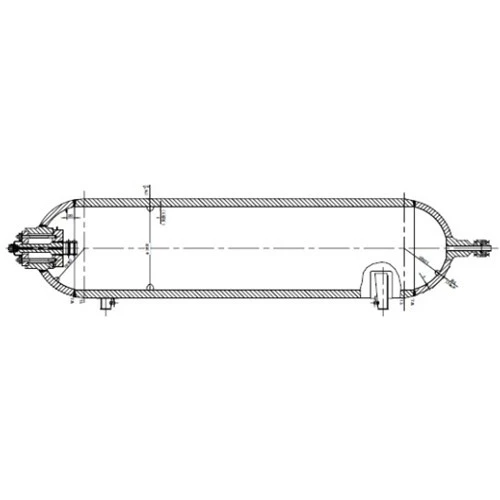

Liquid oxygen tanks, as essential equipment for storing liquid oxygen, play a crucial role in modern industry and scientific fields. Their design and performance directly affect the safe storage and efficient utilization of liquid oxygen. This article will provide a detailed overview of the structural features, performance advantages, and safety precautions for the use of liquid oxygen tanks, offering a comprehensive understanding of the importance of this critical equipment in liquid oxygen...