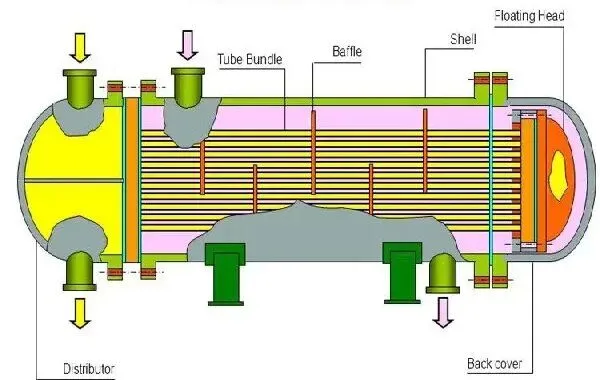

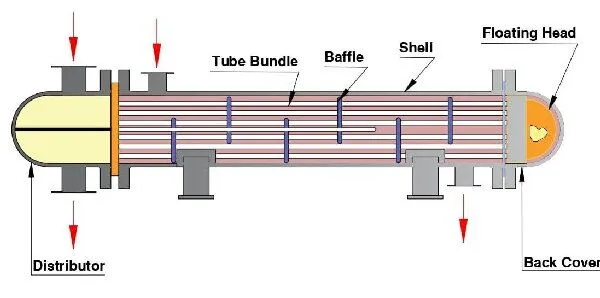

The Unique Advantages of Floating Head Heat Exchangers

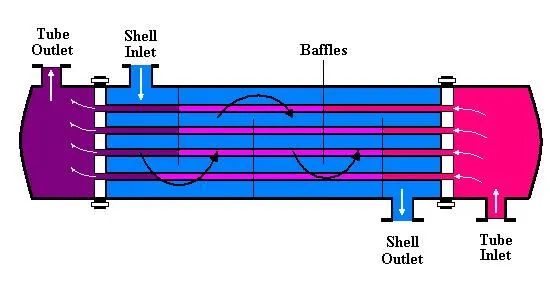

Floating head heat exchangers, as crucial equipment in industrial production, are widely utilized across various process streams due to their excellent heat transfer efficiency and versatile application. Their distinctive floating head structure optimizes the flow path of the medium, significantly enhancing heat transfer effectiveness. Additionally, floating heat heat exchangers are designed for easy operation and maintenance, serving as key tools in improving energy utilization efficiency and production...