An Overview of Activated Carbon Filters for Water Treatment

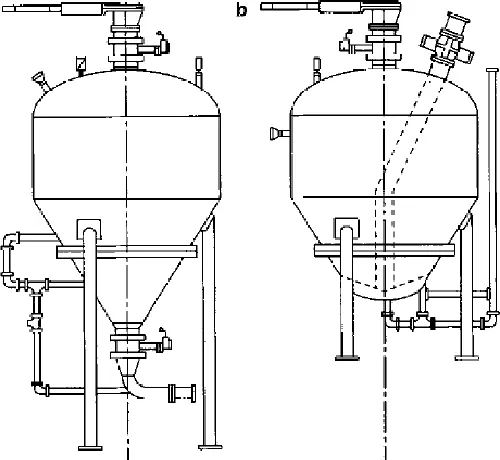

Activated carbon filters are a highly effective type of water treatment equipment, extensively utilized in various industrial processes, households, and water treatment systems. The primary function of activated carbon filters is to adsorb impurities from water, thereby providing clean water quality. Typically, the casing of the filter veseel is made from durable materials such as stainless steel or fiberglass, with the interior filled with activated carbon granules. These filter vessels...