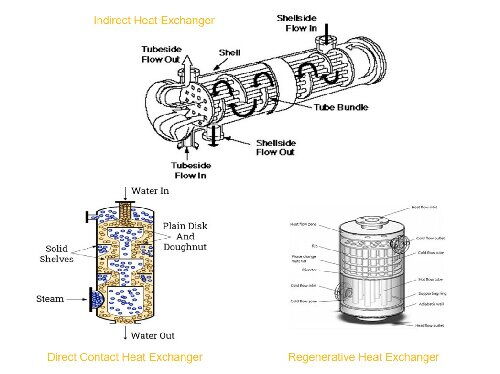

Heat Exchangers: Direct, Indirect, and Regenerative Types

In many industrial and commercial processes, heat transfer is crucial. Heat exchangers are devices designed for the efficient transfer of heat, and they are mainly categorized into three types based on their operating principles: direct contact heat exchangers, indirect heat exchangers, and regenerative heat exchangers. Each type has its unique advantages and applicable scenarios. This article will provide an overview of the working principles, main types, and application areas of these three...